One of the grad students from the nanophotonics lab I developed the microbend apparatus for contacted me regarding a question he had. He was trying to isolate bending and torsional loads in optical fibers to investigate their effects. Introducing pure bending in a fiber is difficult because the fibers have very little torsional stiffness. It's easy to eliminate bends to a twisted fiber by simply adding a bit of tension to the ends. But how do you eliminate twist? There is so little stiffness that you cannot rely on the restoring torque to eliminate small twists in the fiber. The current solution is to coil the fiber very loosely (coiling is just one very long continuous bend) whatever twist is inadvertently introduced by the act of coiling will distribute itself along the length of the entire fiber. In contrast, in fiber optic gyroscope winding, because the coils are so tight, the minor twists in the fiber get trapped between turns of the coil, leaving behind localized residual torsions in the fiber.

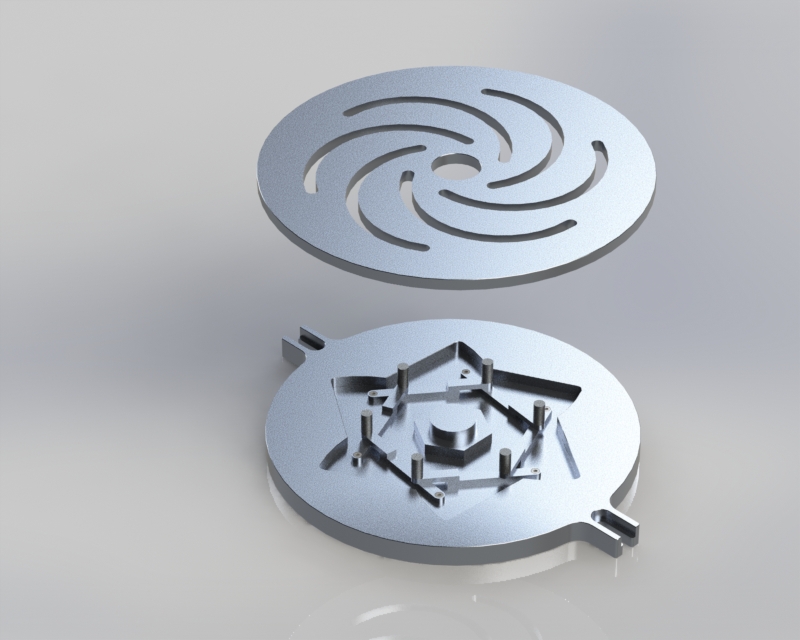

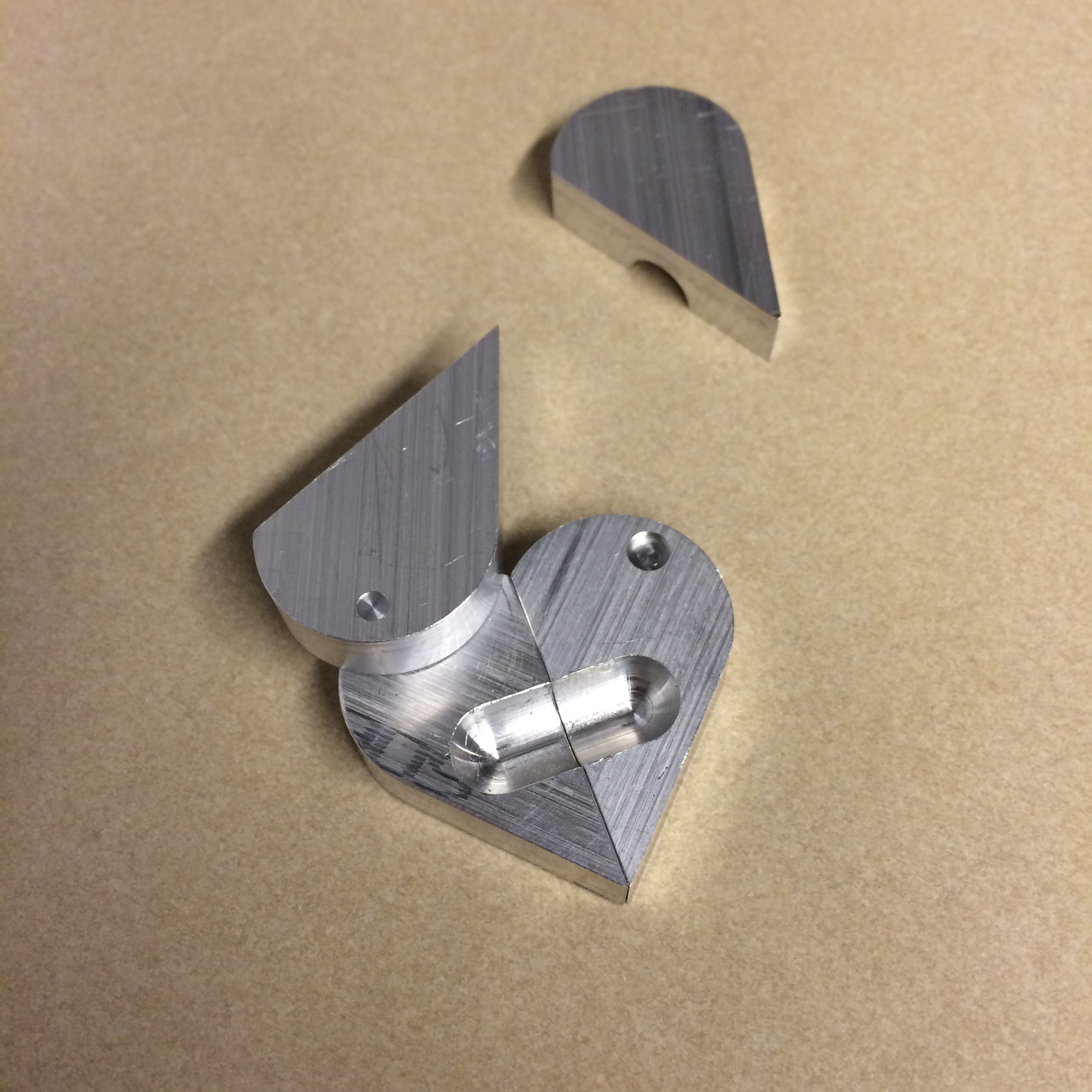

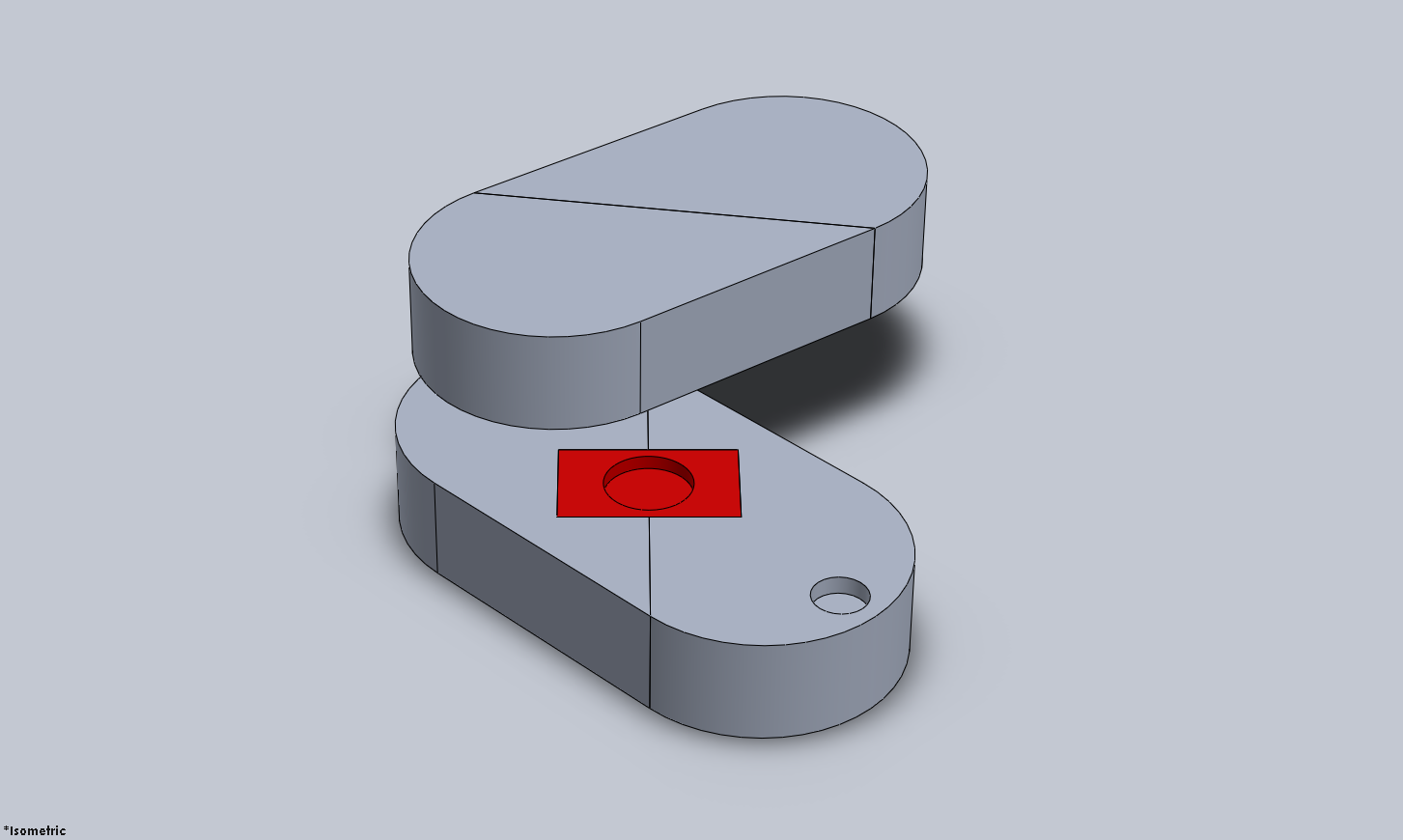

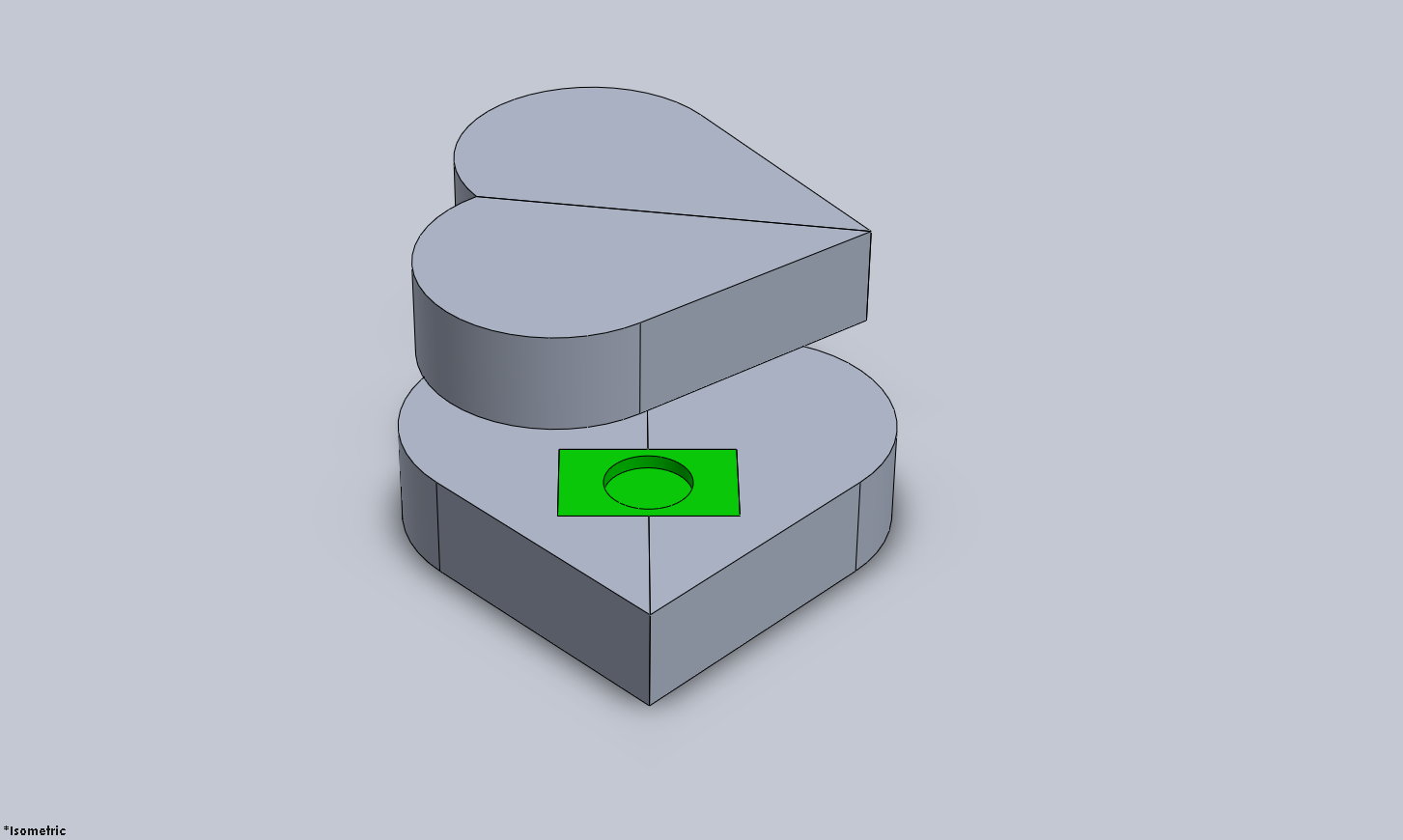

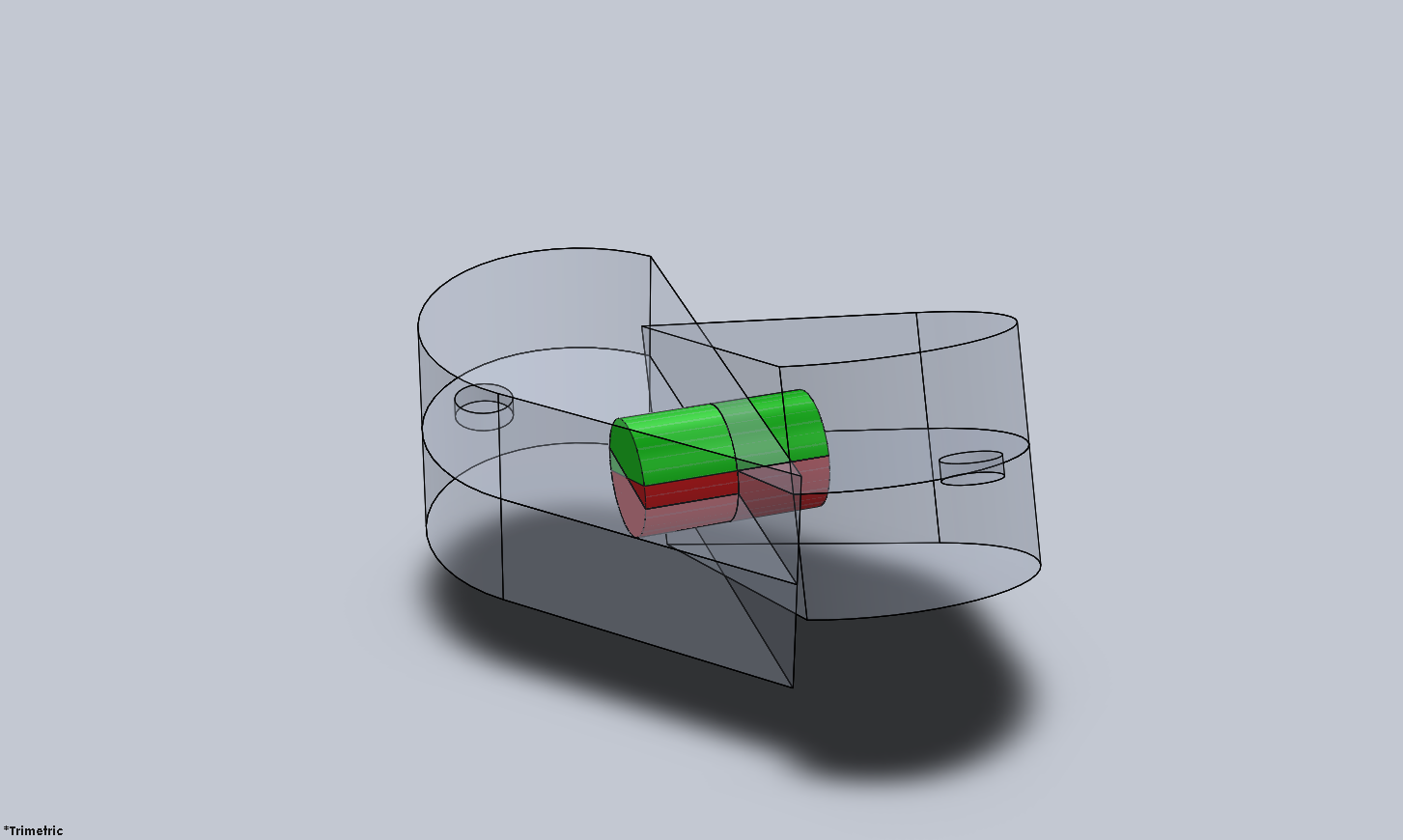

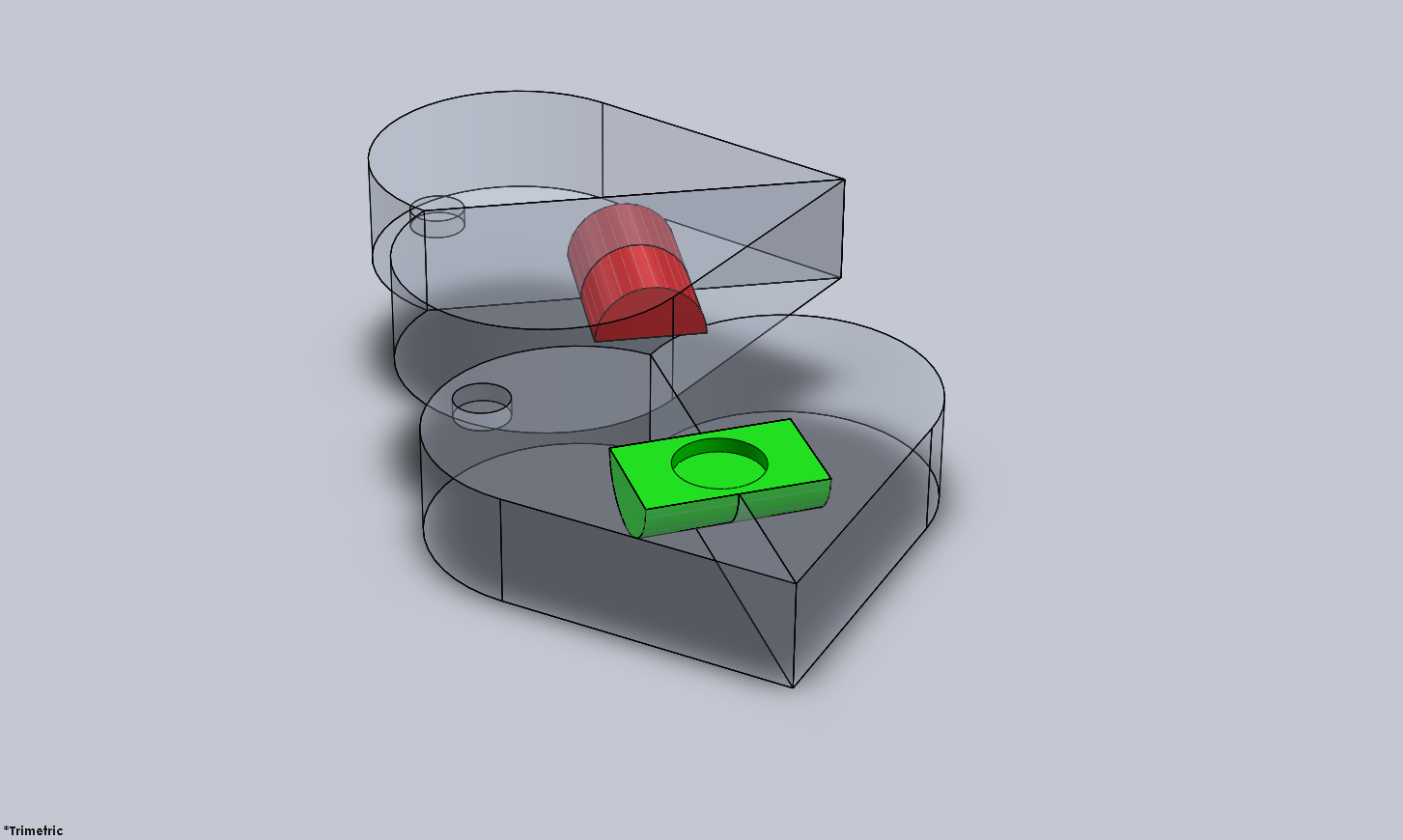

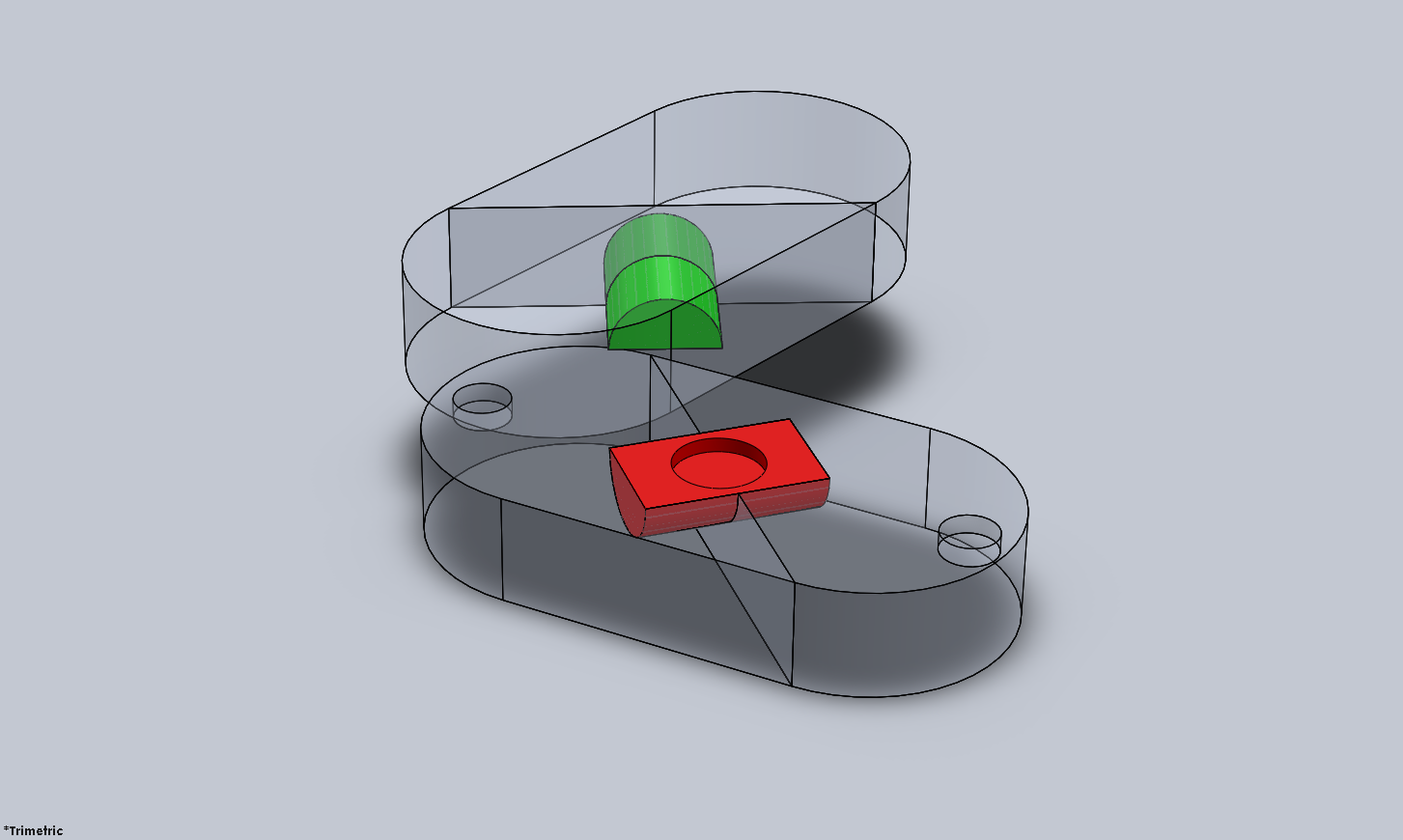

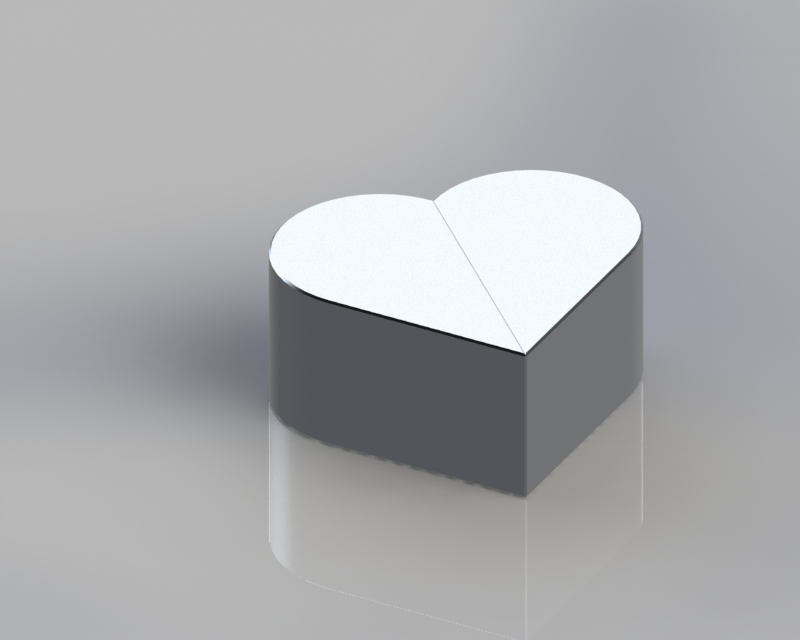

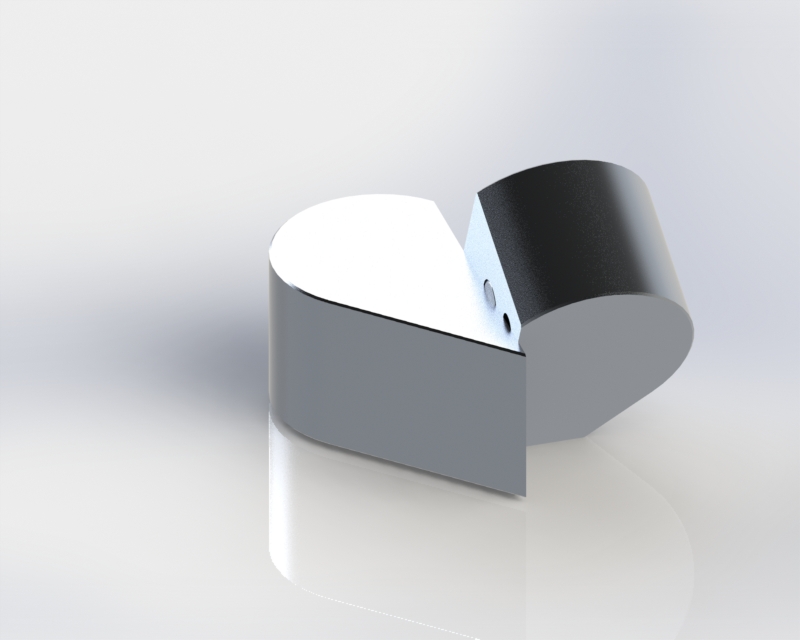

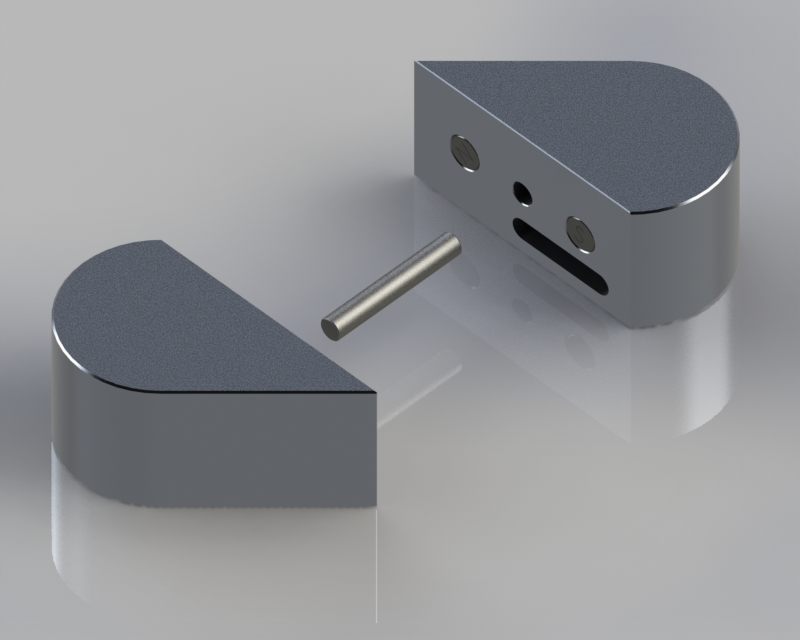

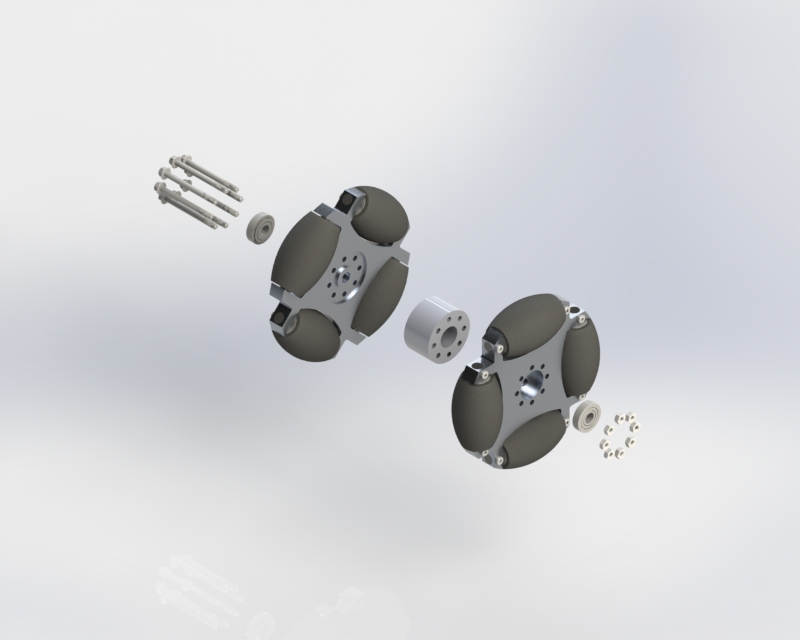

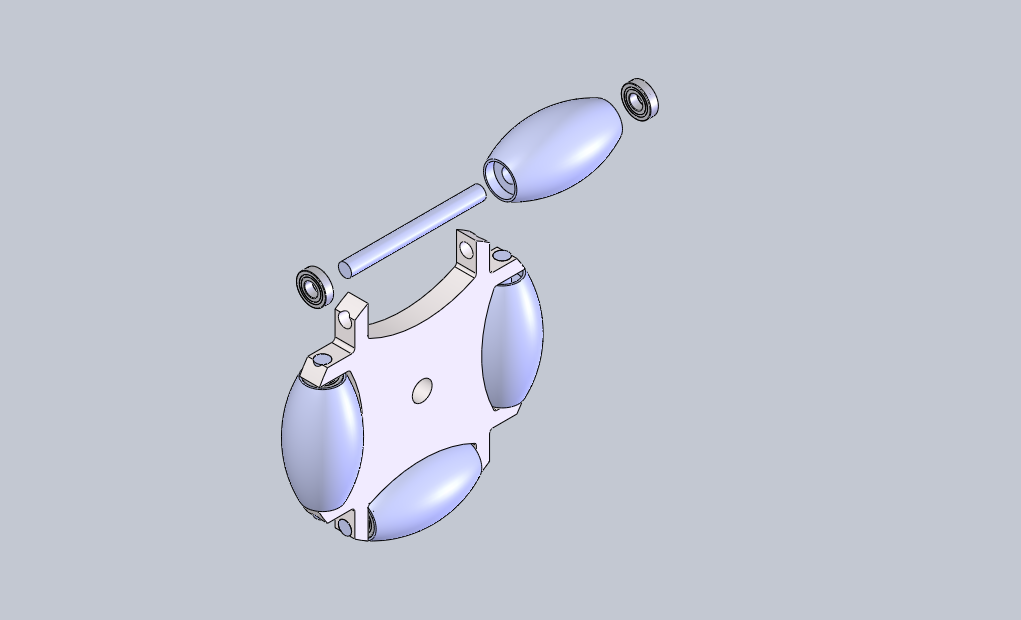

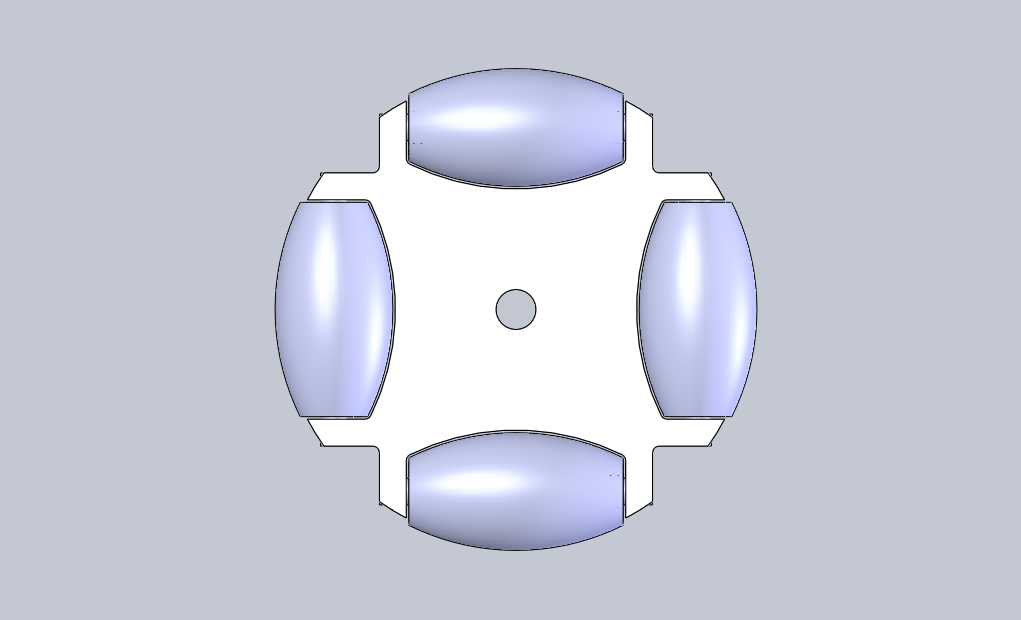

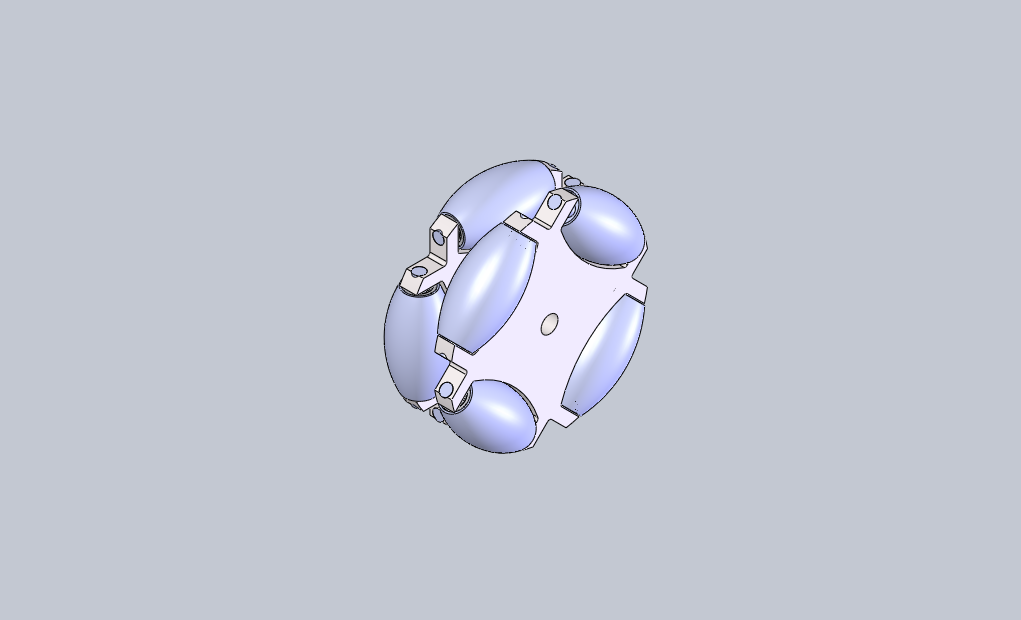

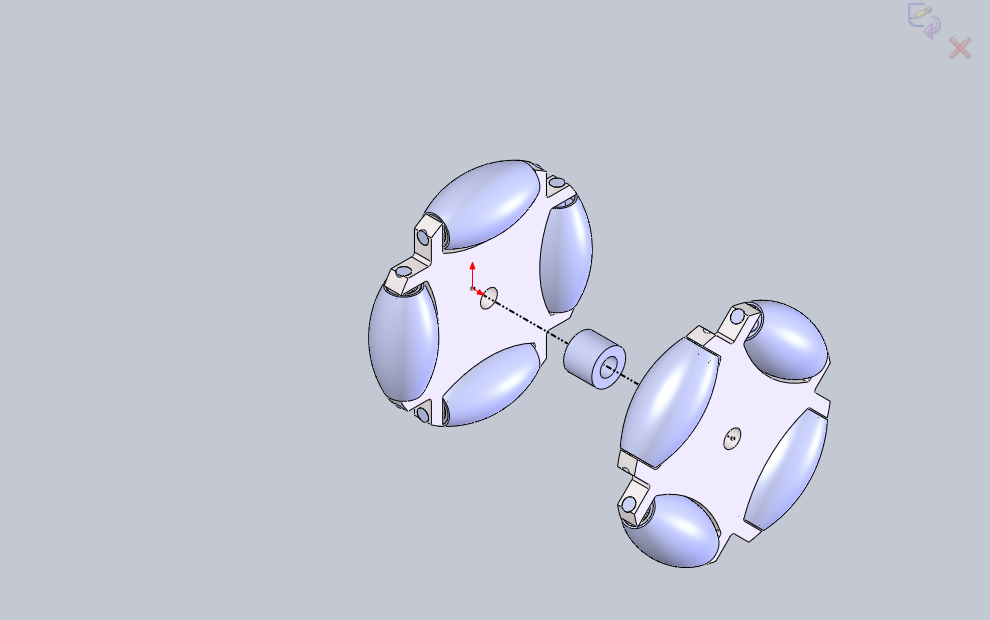

The downside to a loose coil is that it is very hard to get each turn in the coil to the same diameter. A constant bending radius is required for accurate measurements. We decided to use an iris diaphragm mechanism to control the diameter of 6 pins, which the fiber will loosely be wrapped around as guides. This way, a very minimal amount of tension could be used to make sure the coils are all the same diameter, and the diameter can be adjusted using the iris mechanism. To go along with this, it would be helpful to have a limited slip fiber clamp and constant force spring loaded spool so the diameter could be adjusted either direction without having to manually pick up slack in the fiber or loosen the coils to reduce the tension.

One other alternative to this 'loose coil' solution is to actively measure and correct the fiber twist. However, this method seems overly complex. It really depends on how much twist is tolerable. Once that is quantified, we will be able to determine what type of solution is required. I have a feeling the tolerance will not be so tight as to necessitate some type of active system. But I wonder if there is a better solution for an active system? Perhaps if instead of wrapping the fiber around pins, we could wrap it around an expanding cylinder controlled by the iris mechanism. But I have no idea how that could work. Time to start brainstorming...