The specs for this design have been developed. Recently I've been working on making the molds to cast the QD plastic in. I purchased a tin-cure silicone molding media which meets the temperature requirements of the vacuum oven the plastic will be cured in. I selected tin cure over platinum cure because we have access to a vacuum chamber to de-gas the molding media as it cures, and it's a bit cheaper than the platinum cure. It also works with a wider variety of materials. The library life is not as long as the platinum cure, but that is not really a concern for this application.

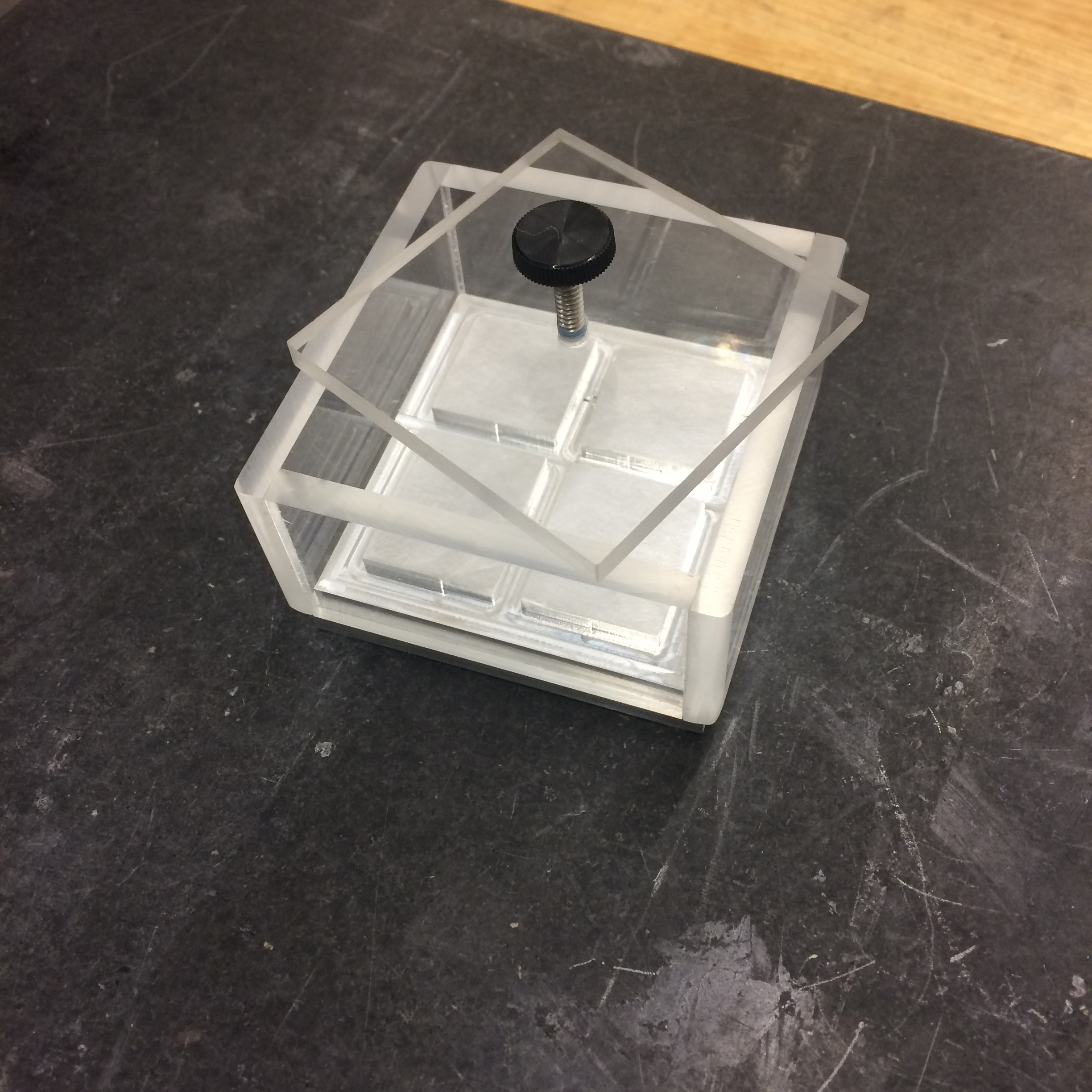

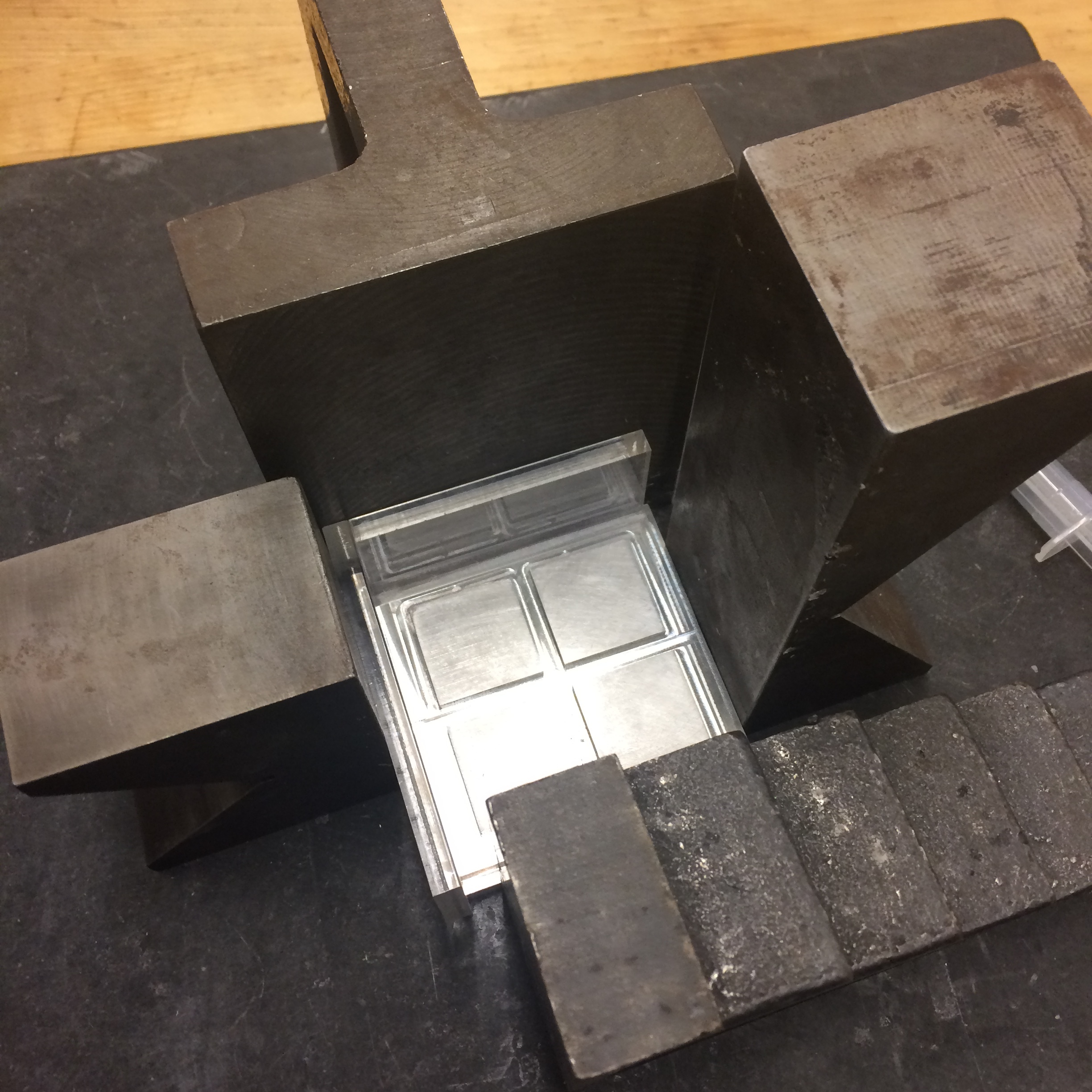

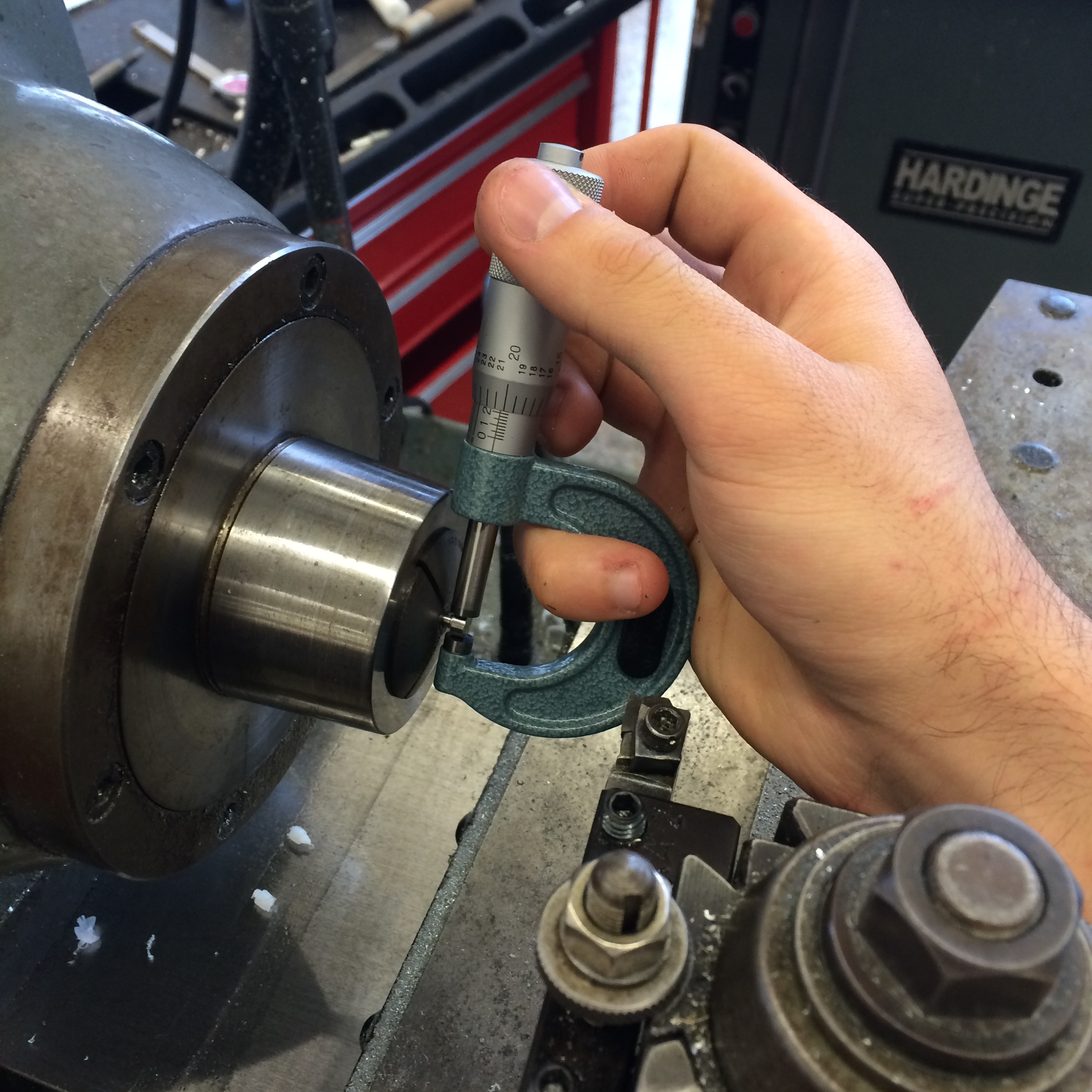

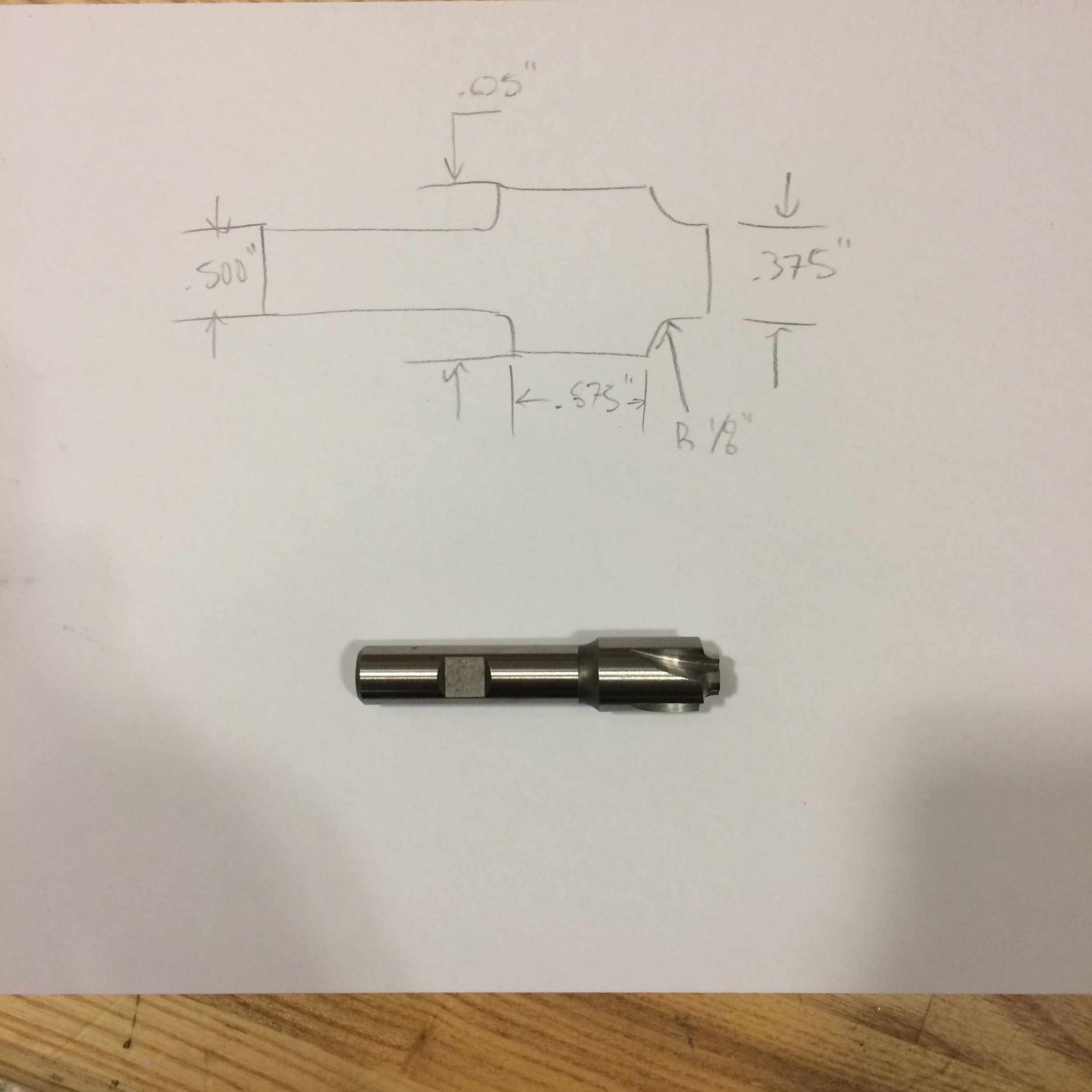

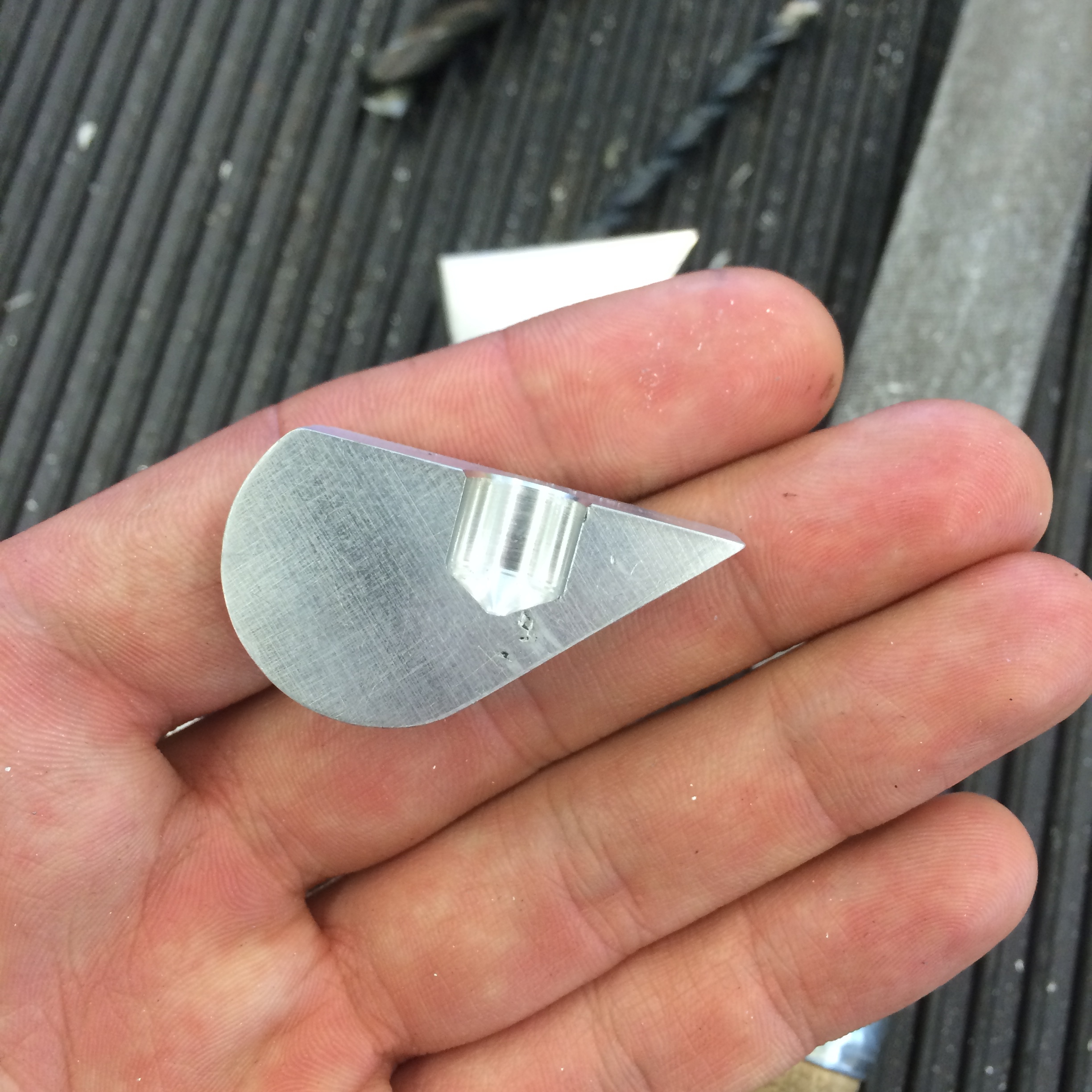

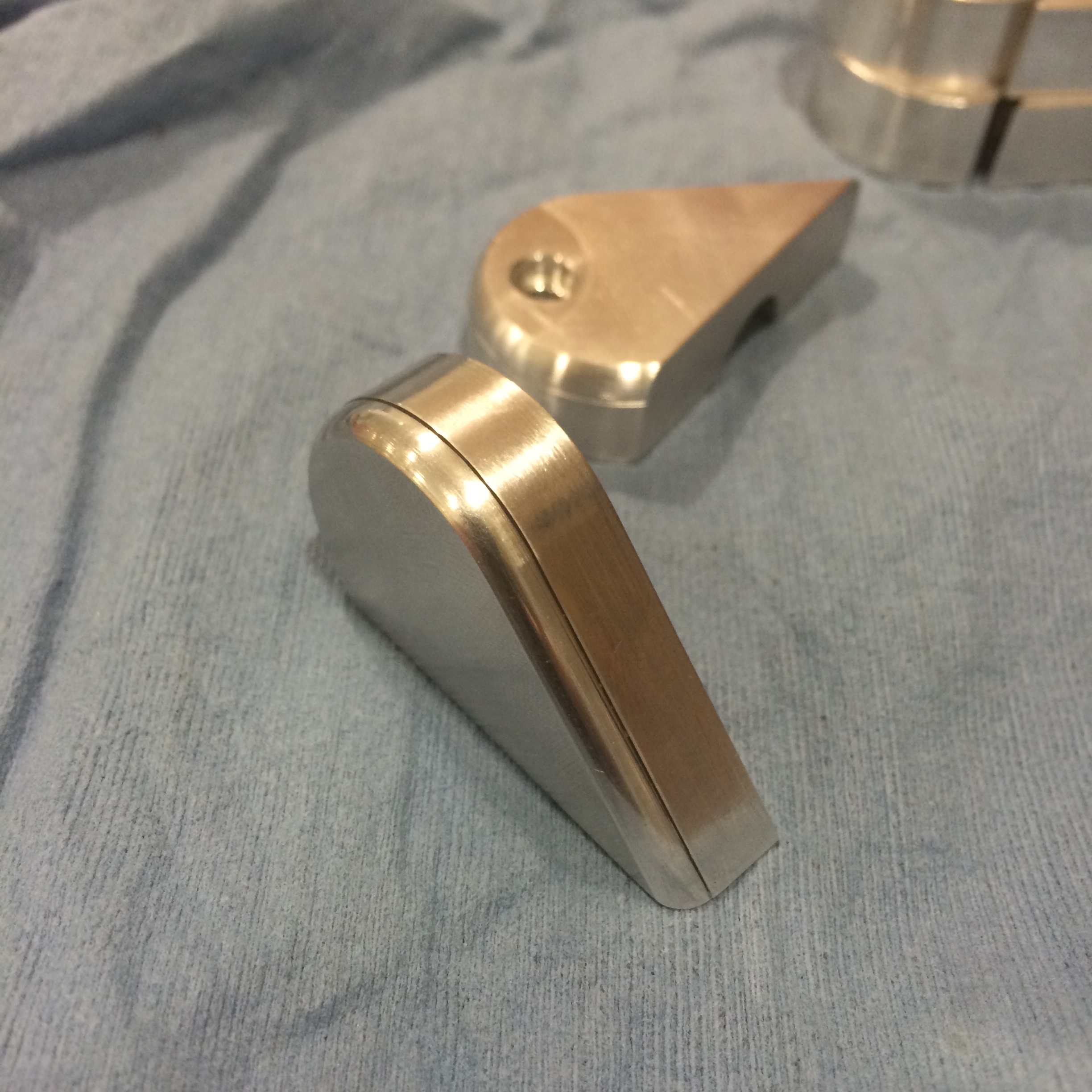

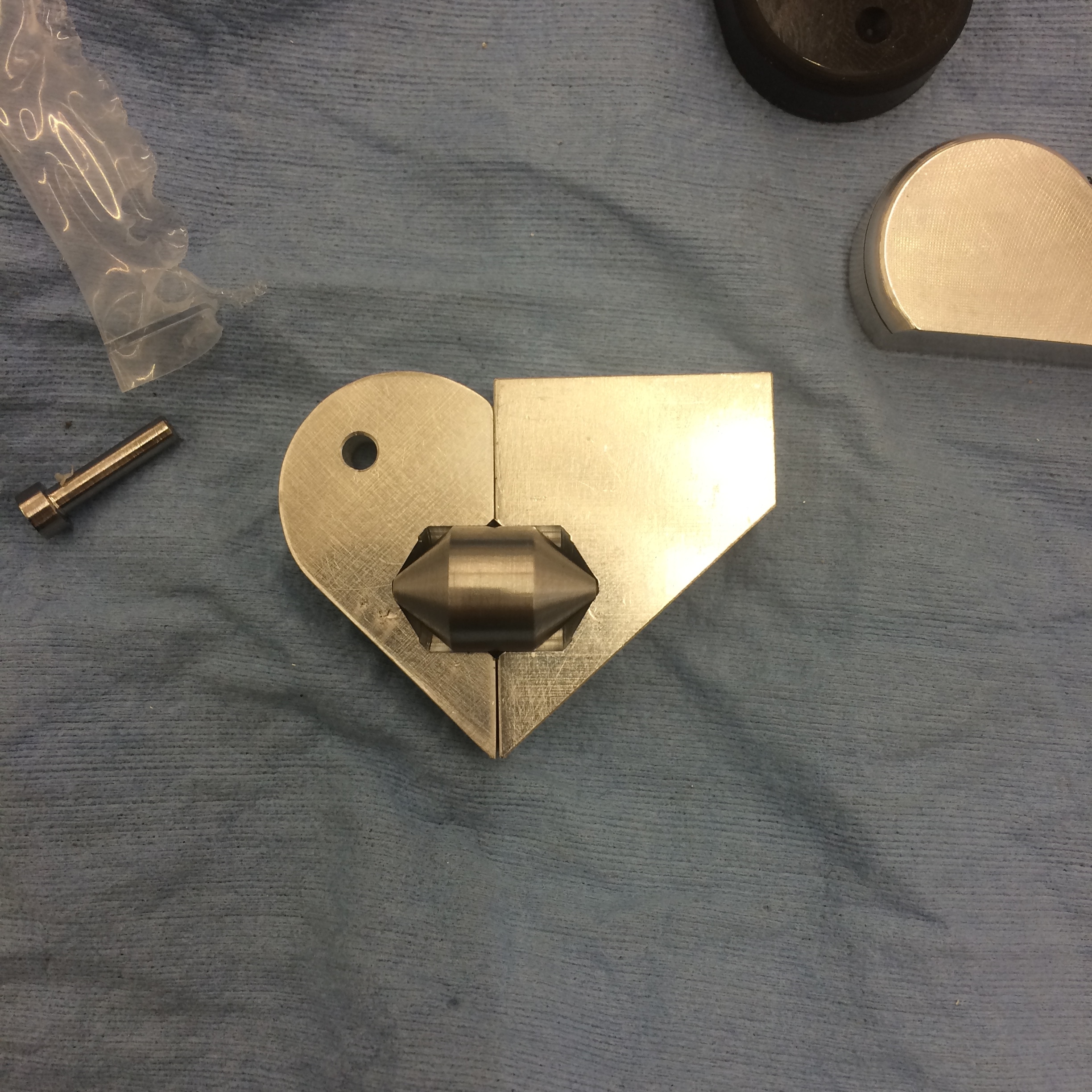

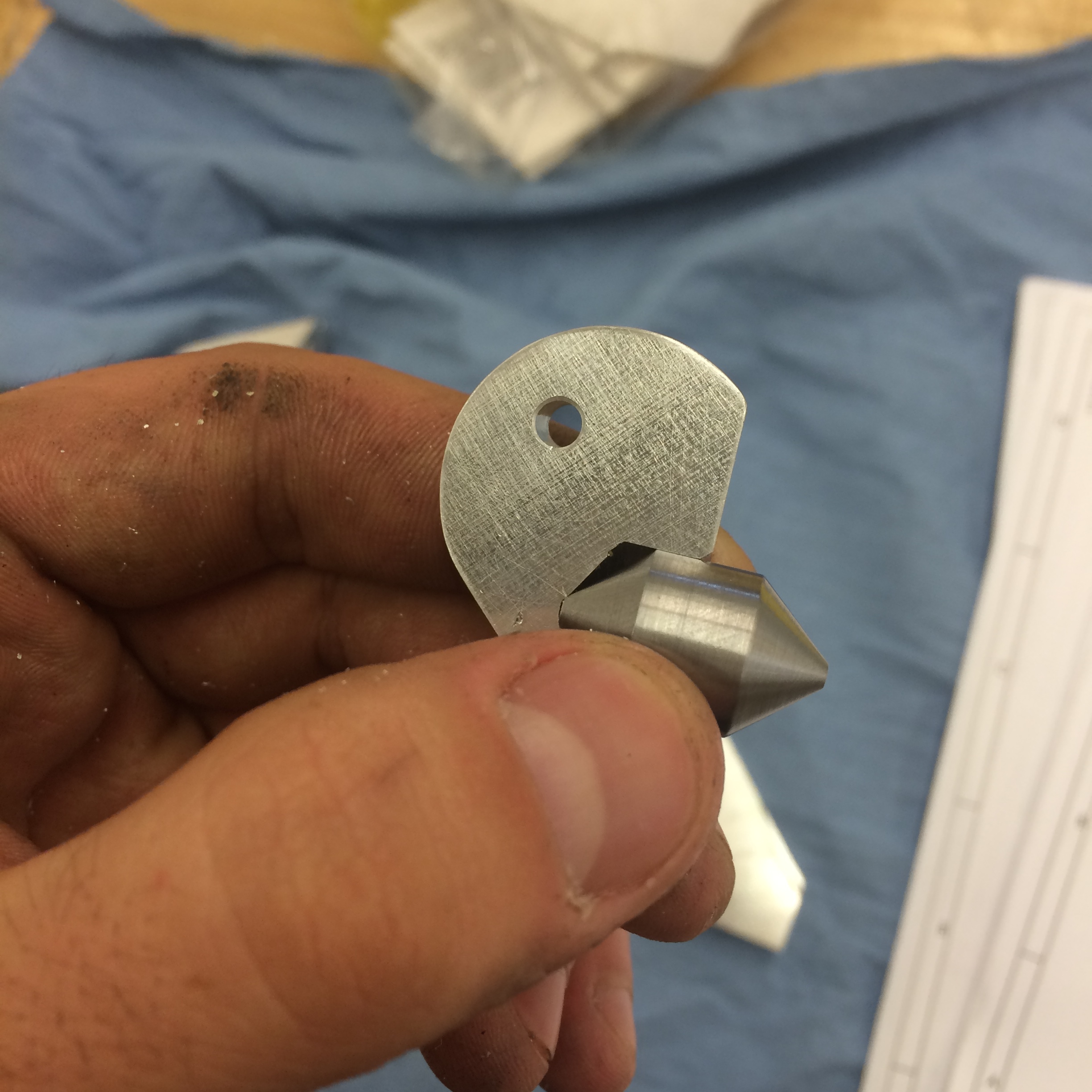

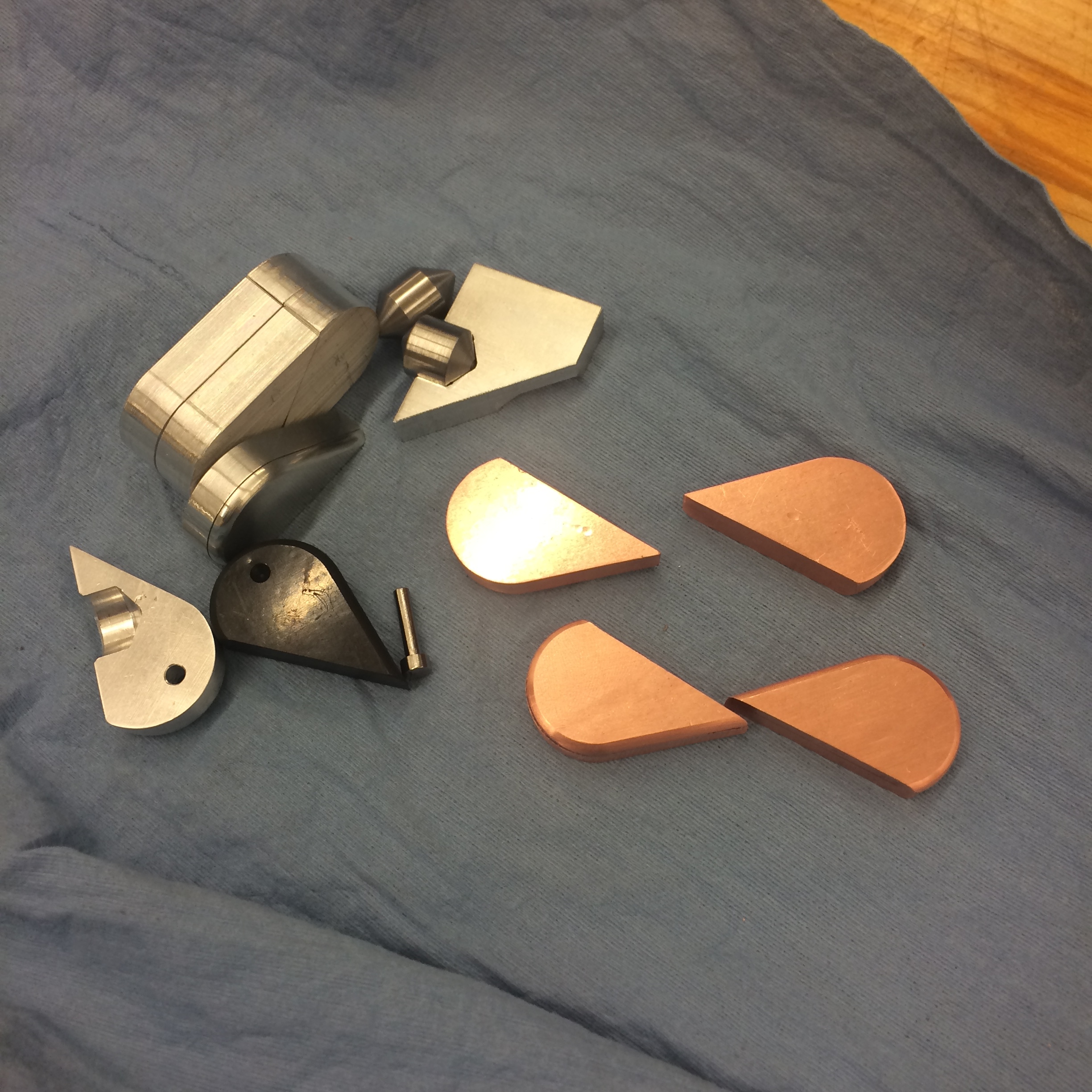

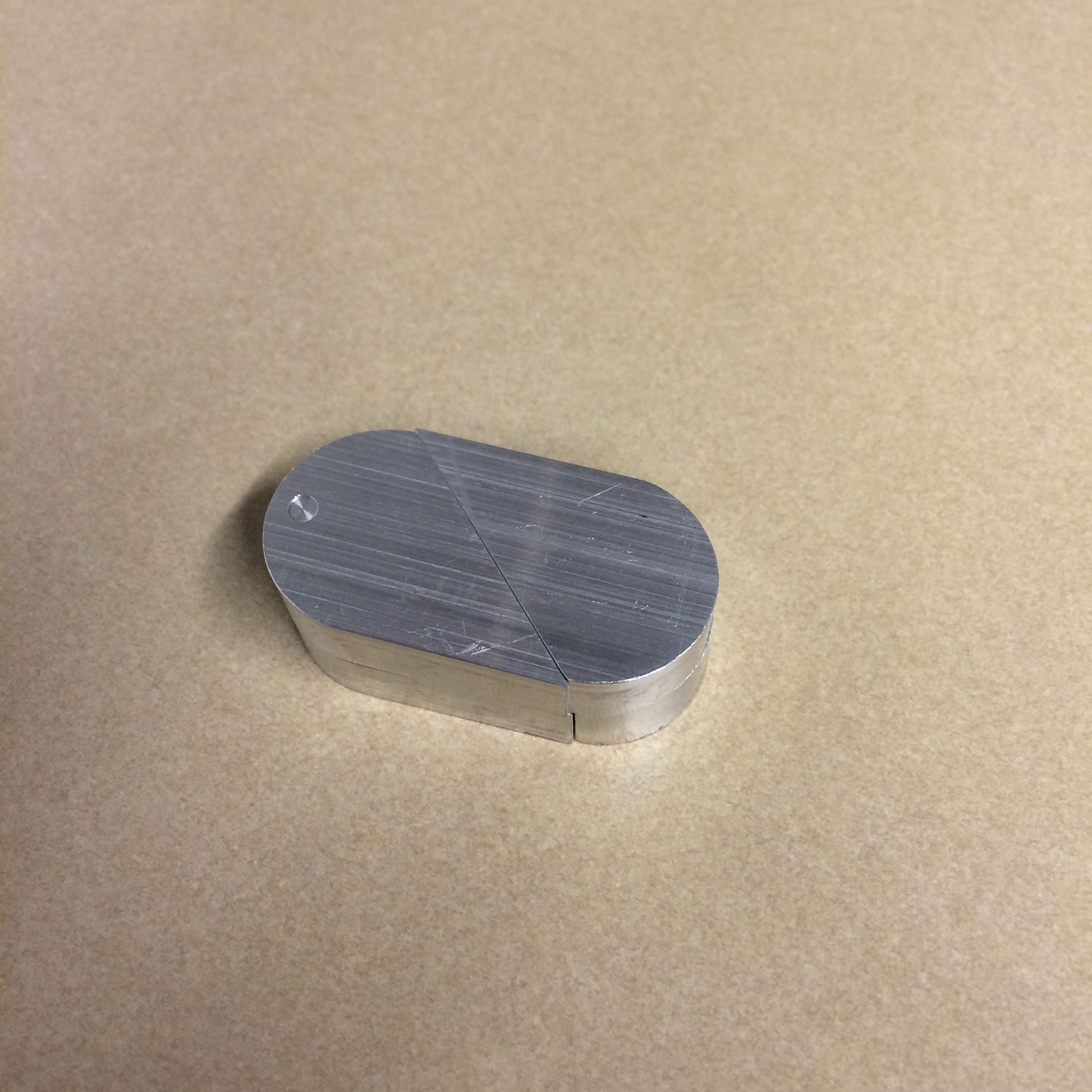

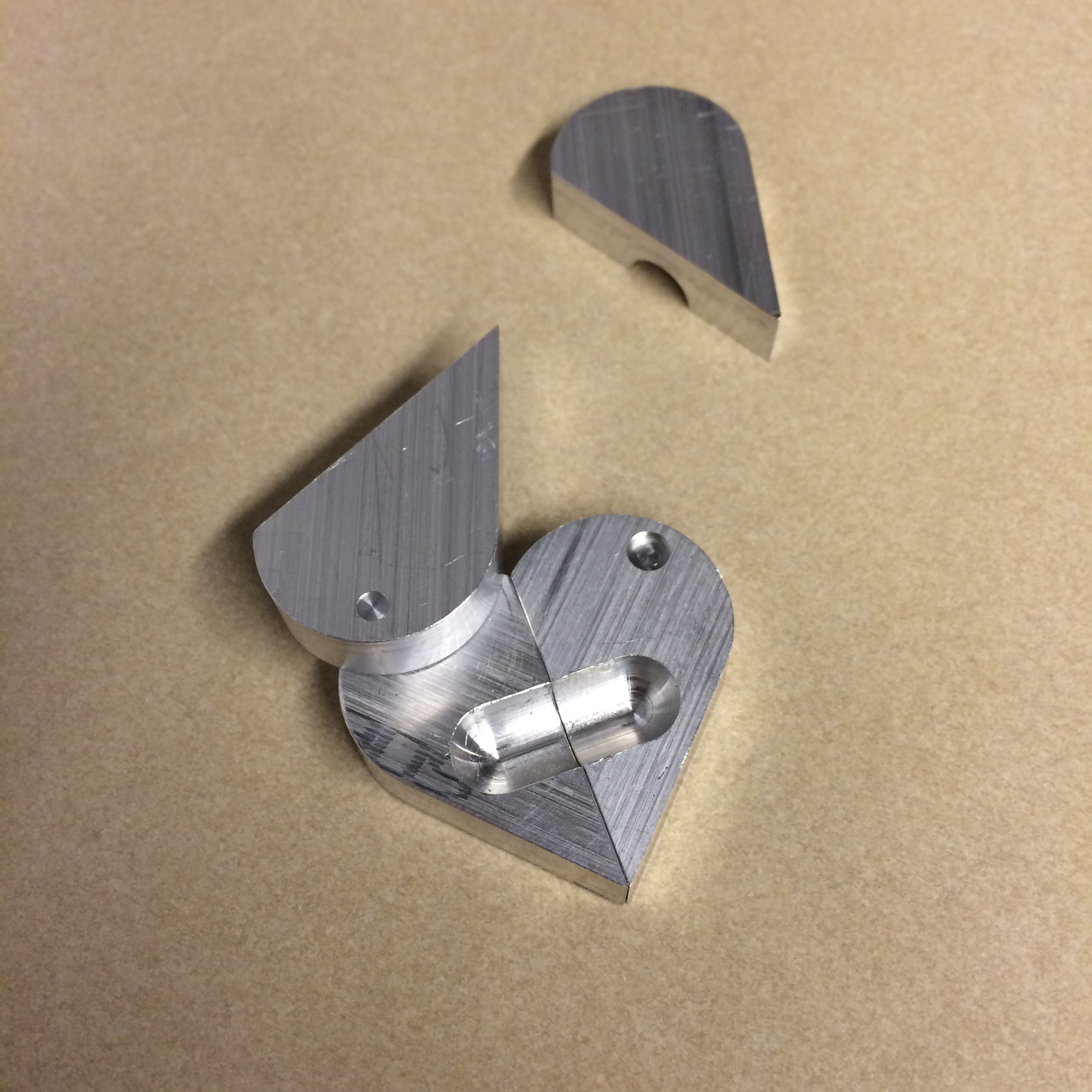

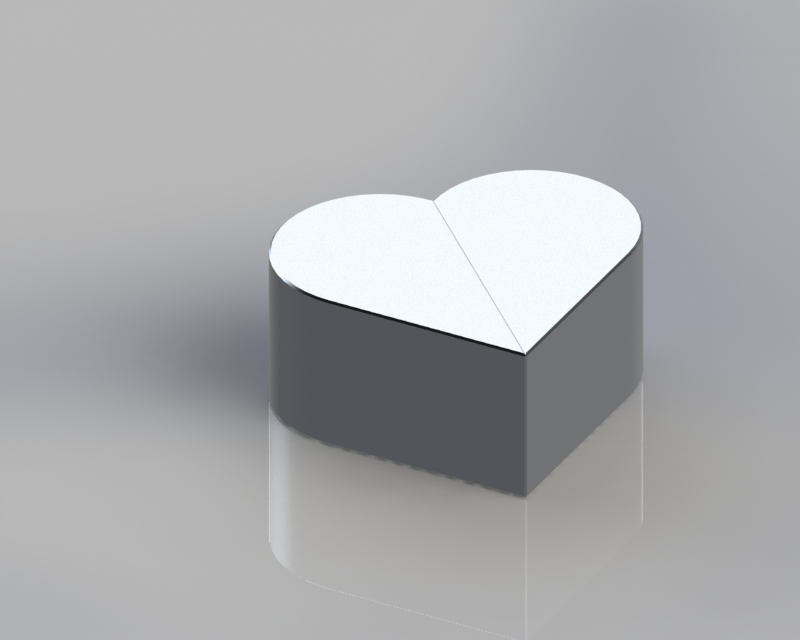

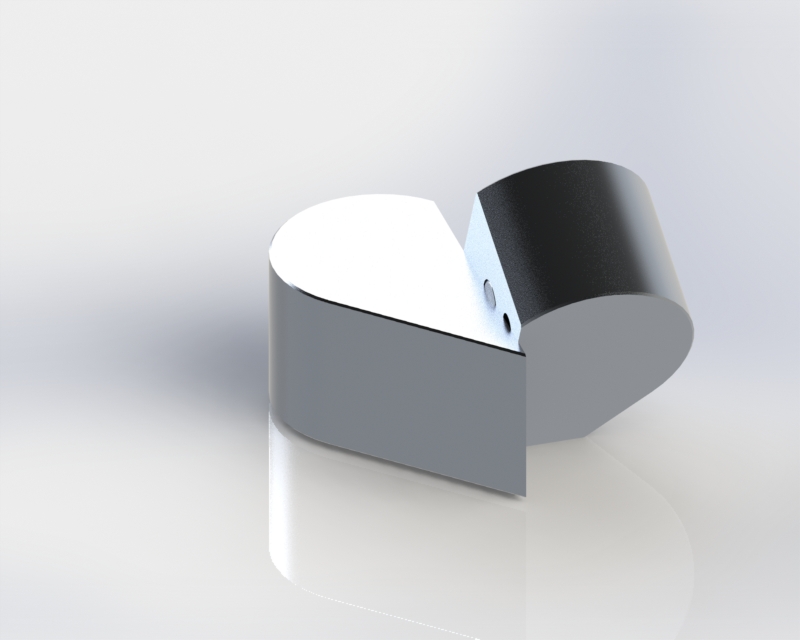

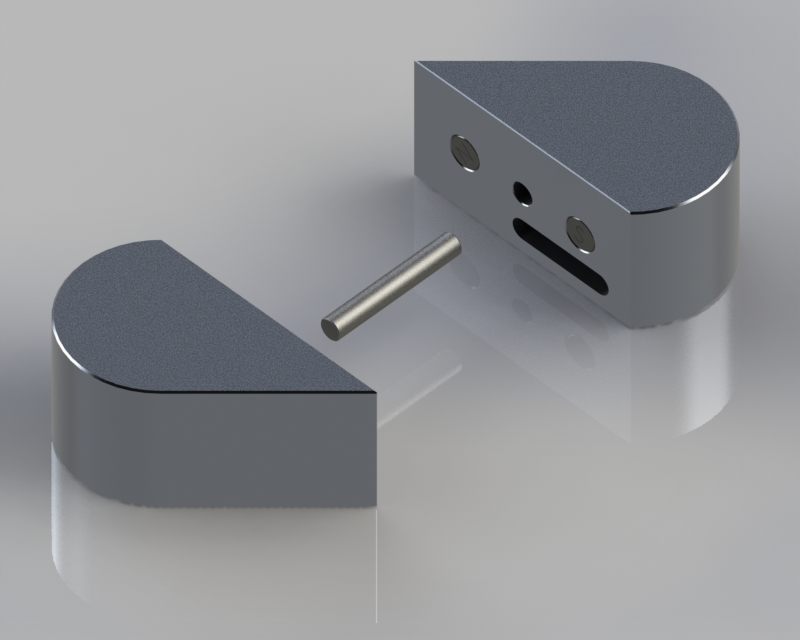

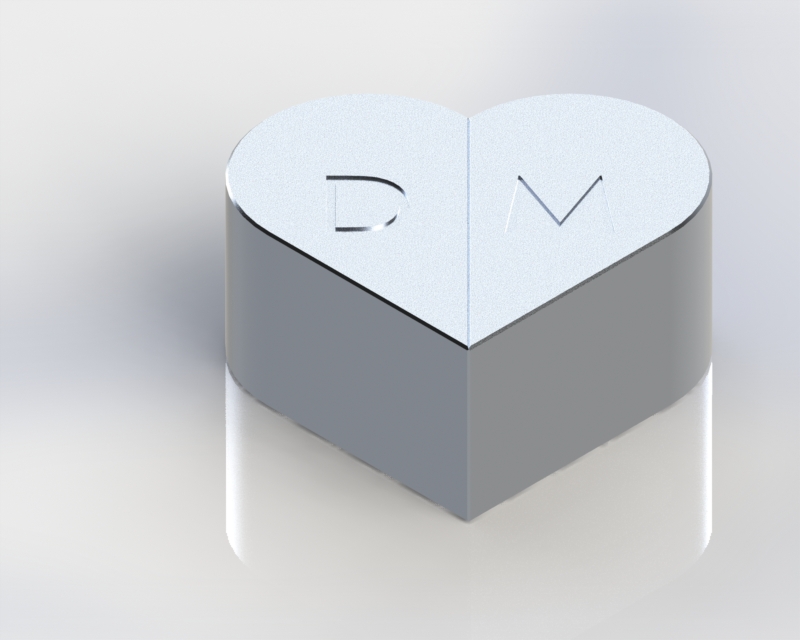

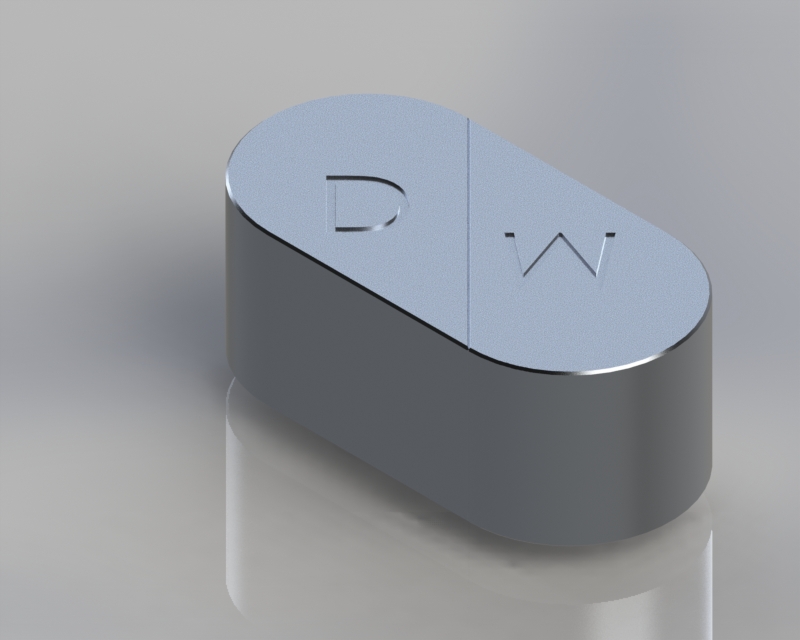

I milled the positive for the mold out of aluminum. I then lasercut some acrylic to form a cavity around the positive in which to cast the mold media which will become the negative. The result will be a simple open faced mold. If the results from this mold are no good, we may try a 2 part mold, but I think a 2 part mold would be overkill for this part.

Up Next:

I have a design for the box, but I need to make sure it can be made with an efficient use of materials, and easy to assemble, as we will be making many of these devices.

I need to further embody the electrical design by selecting a UV source. I am having trouble designing a UV LED array that meets the light intensity requirements to activate the QDs while being at a reasonable cost. The UV LEDs are quite expensive, and I'd need a lot of them. I'm considering reverting to a fluorescent source if it turns out to be cheaper.