One of my tasks as an engineering education developer at BU is to beef up the content of some activities with some higher level concepts. Recently I've been working on an activity where students get to design, build, and test their own wind turbines. Right now the activity works great with middle school students, but we want to improve the activity and make it more challenging so that we can bring it to high schools as well. The activity uses store bought wind turbine kits with a variety of blade types. Students can choose the material of the blades, the size of the blades, how many blades, and how to angle the blades. Then, once they've built their turbine, it's placed in front of a box fan and connected to a volt meter to measure the power. After their first design, students are allowed to make changes and test a second time before the teacher gathers everyone for a recap.

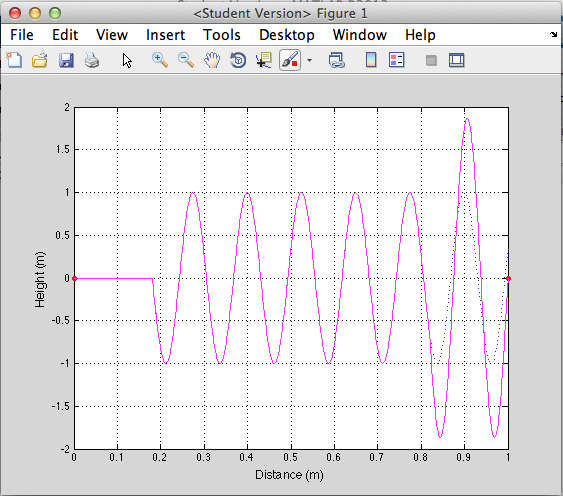

Our goal is to enable students to use data obtained from their first test to quantitatively evaluate and improve the performance of their design. This requires some type of quantitative analysis of the wind turbine. So I began doing some math. I just finished a course in aerodynamics, where we learned all about airfoils and wings, so I felt I had a good handle on the concepts at hand. After all, a wind turbine is just a bunch of rotating wings, right?

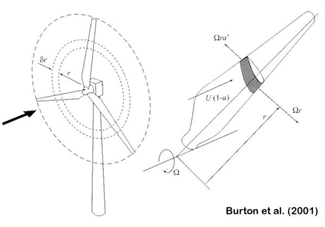

Well regardless, that's how I modeled it. But unlike regular airplane wings, rotating wings (aka blades) don't all feel the same wind. The ends of the blades travel much faster than the inward portions, meaning the airspeed for that section of blade is faster. So the normal approach doesn't work in this case, because the wind is quite different everywhere across the wing.