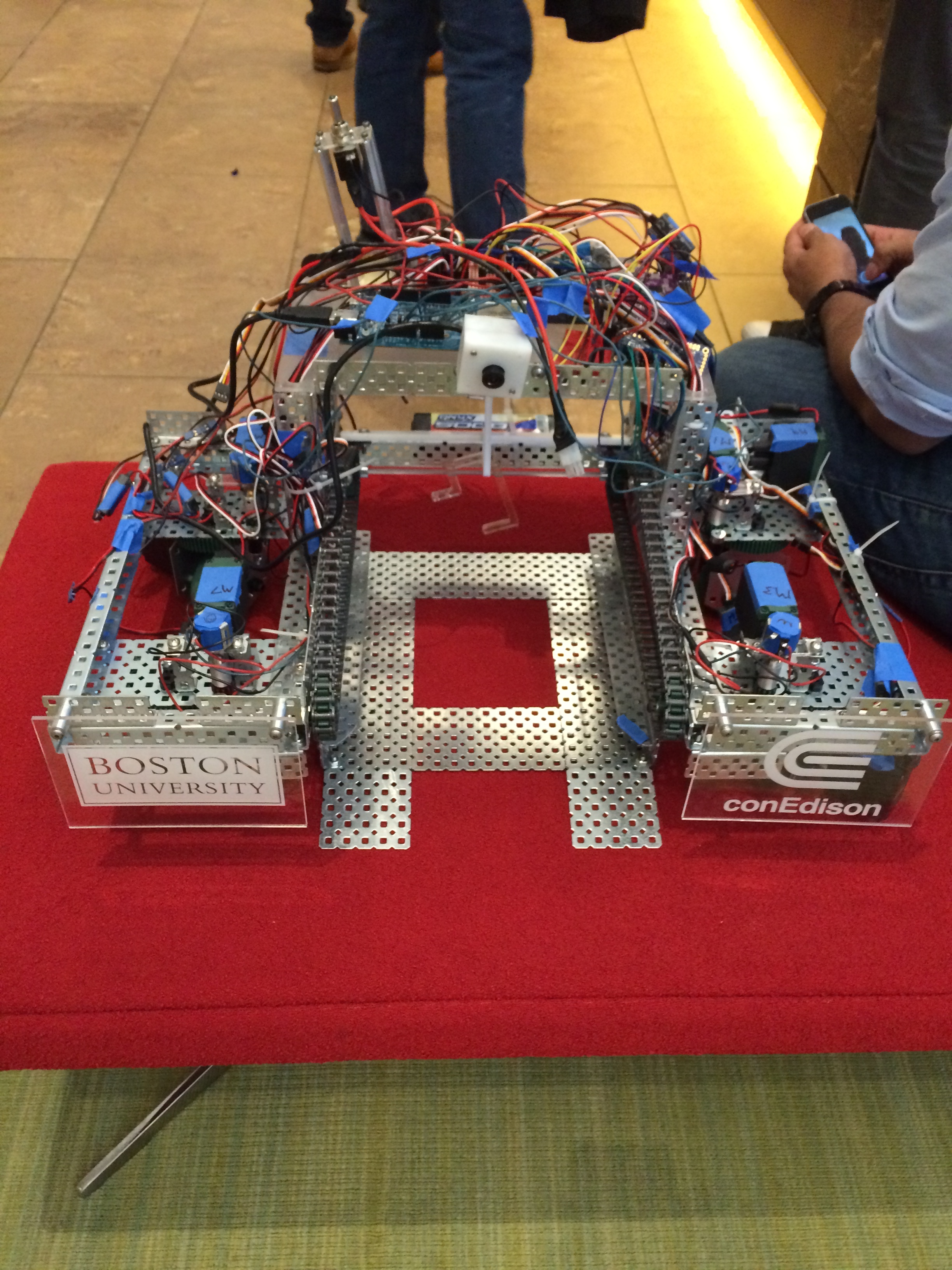

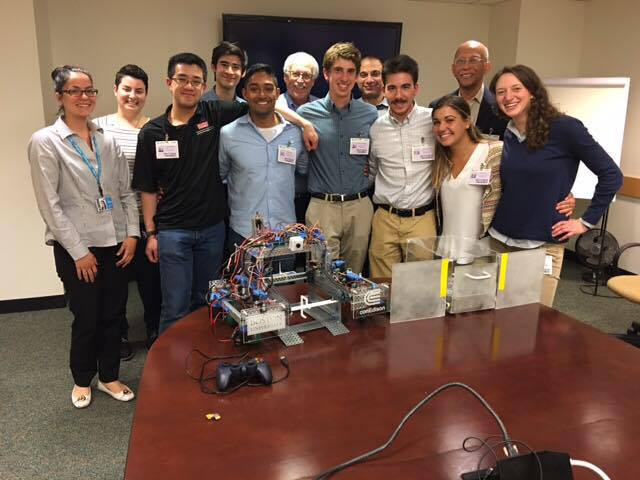

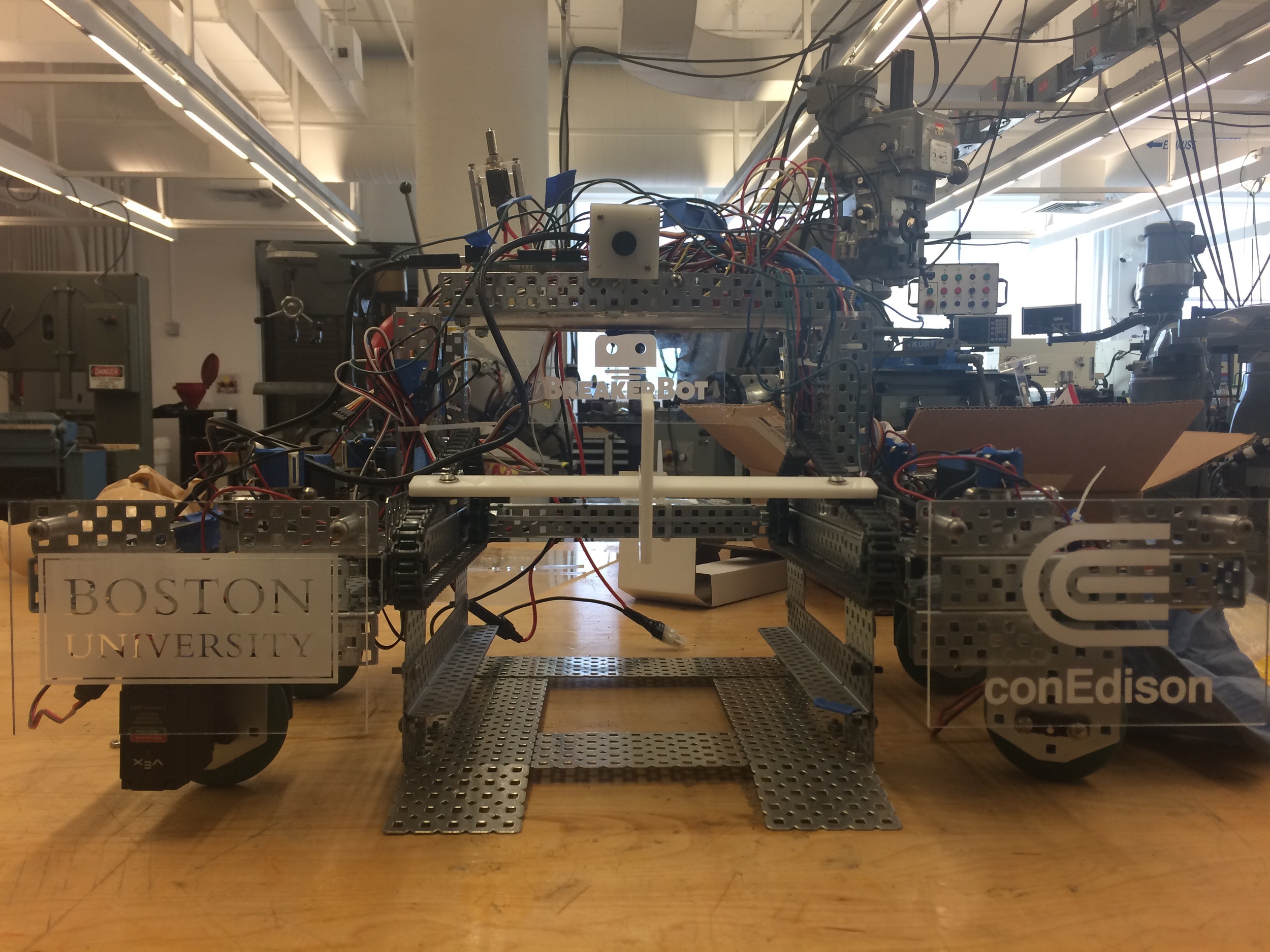

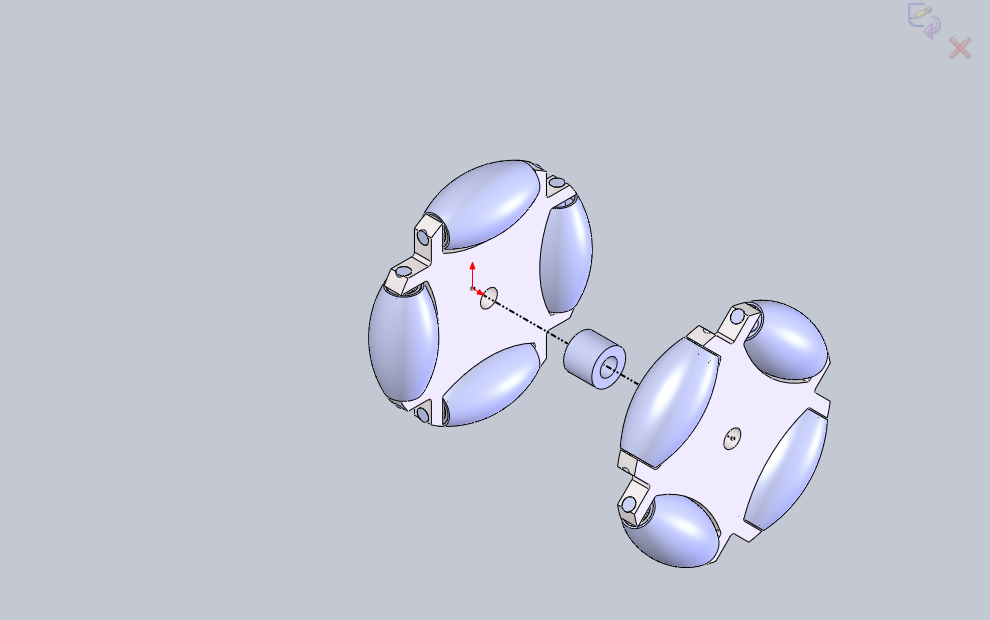

Yesterday we visited ConEdison in my hometown of NYC to present our Senior Capstone project, BreakerBot. The goal of this phase of the project was to convince ConEd to continue future phases of the project at BU by delivering a prototype that could:

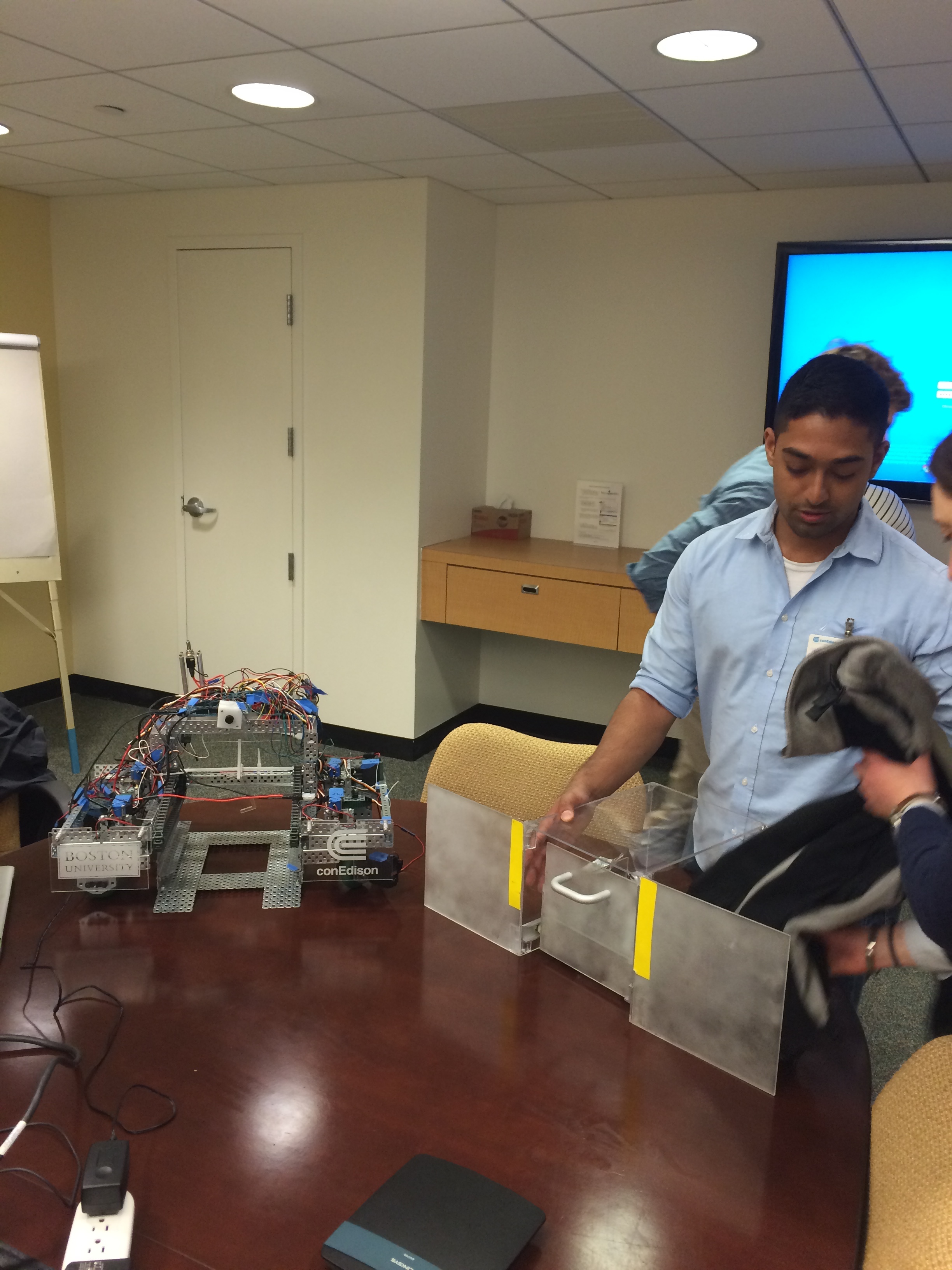

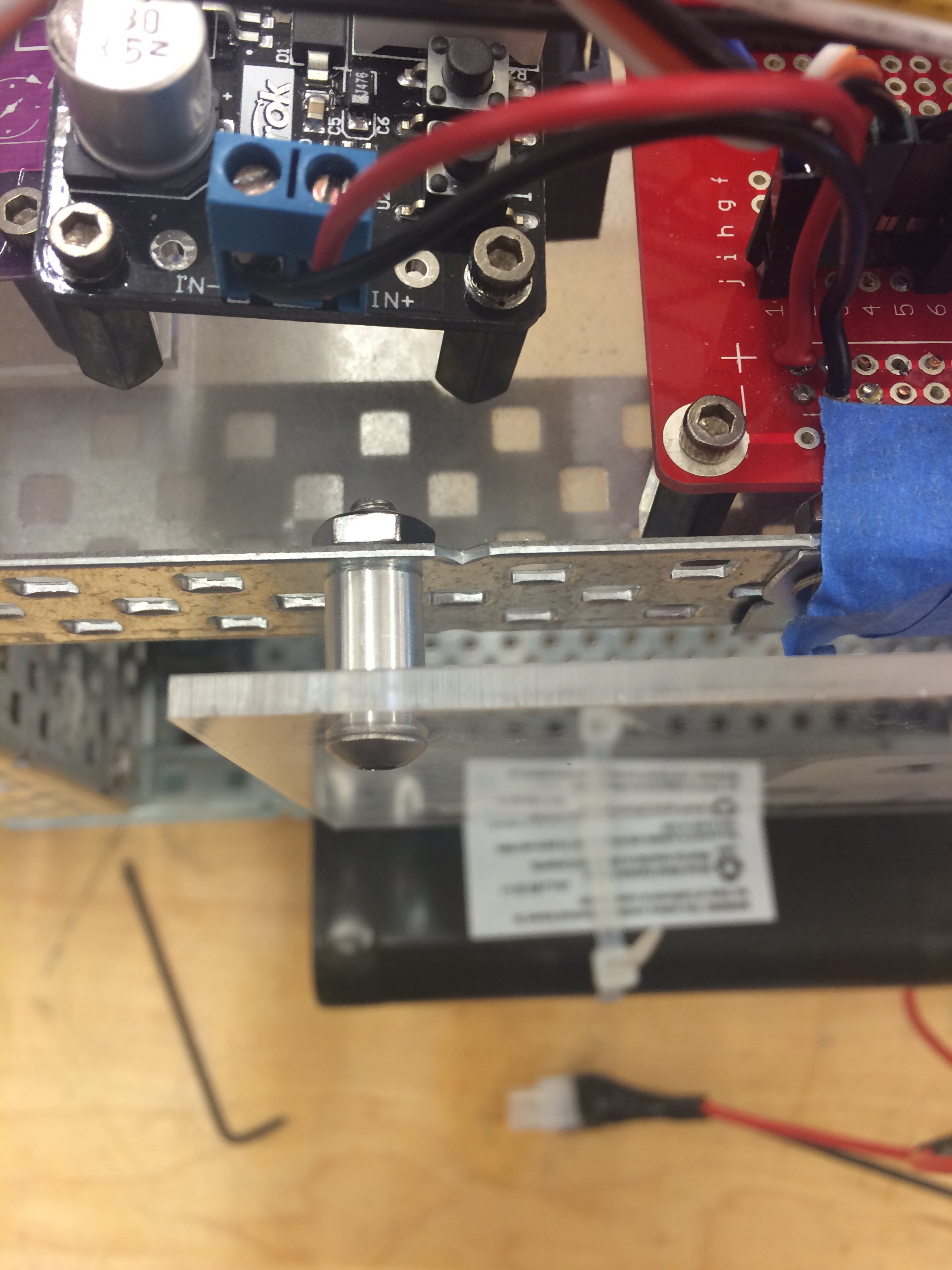

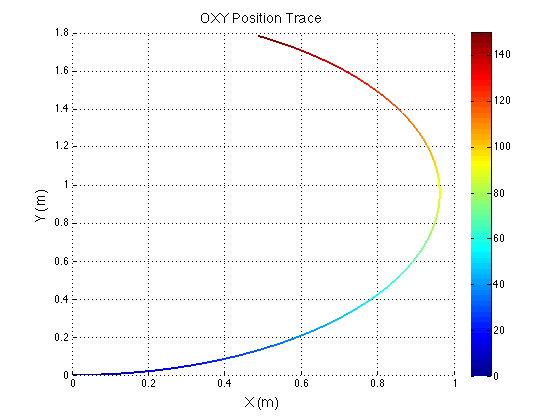

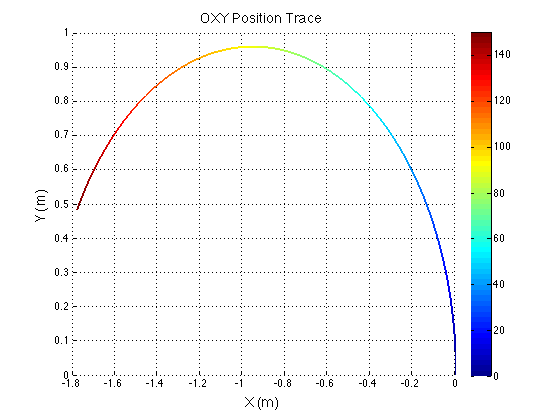

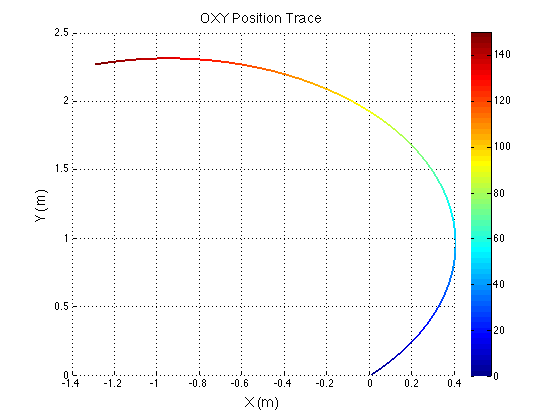

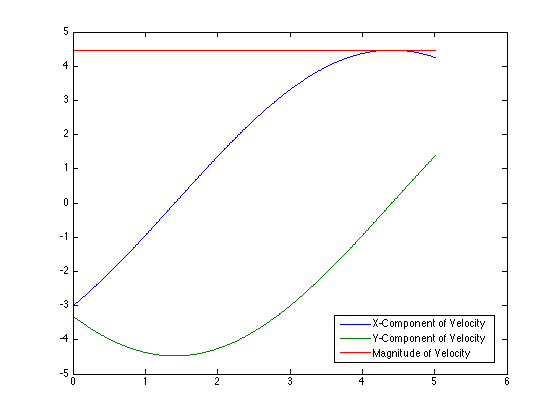

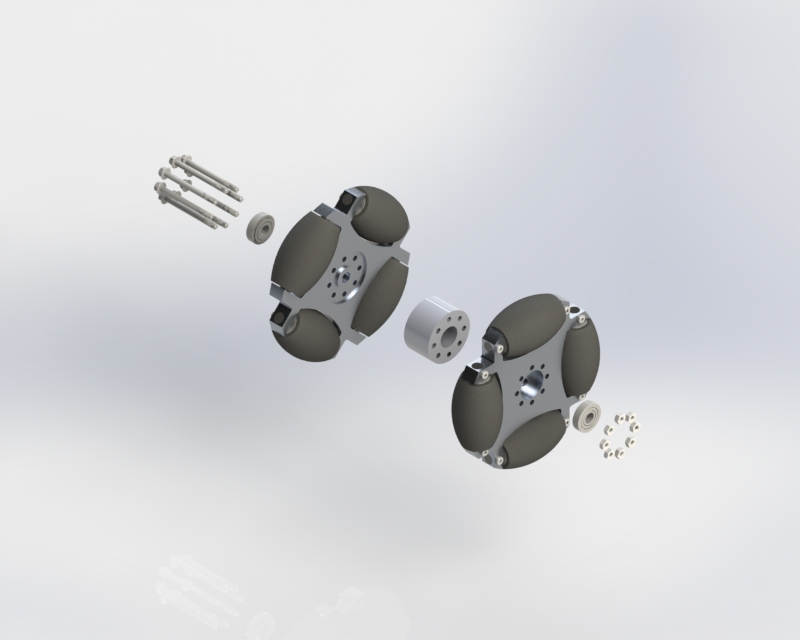

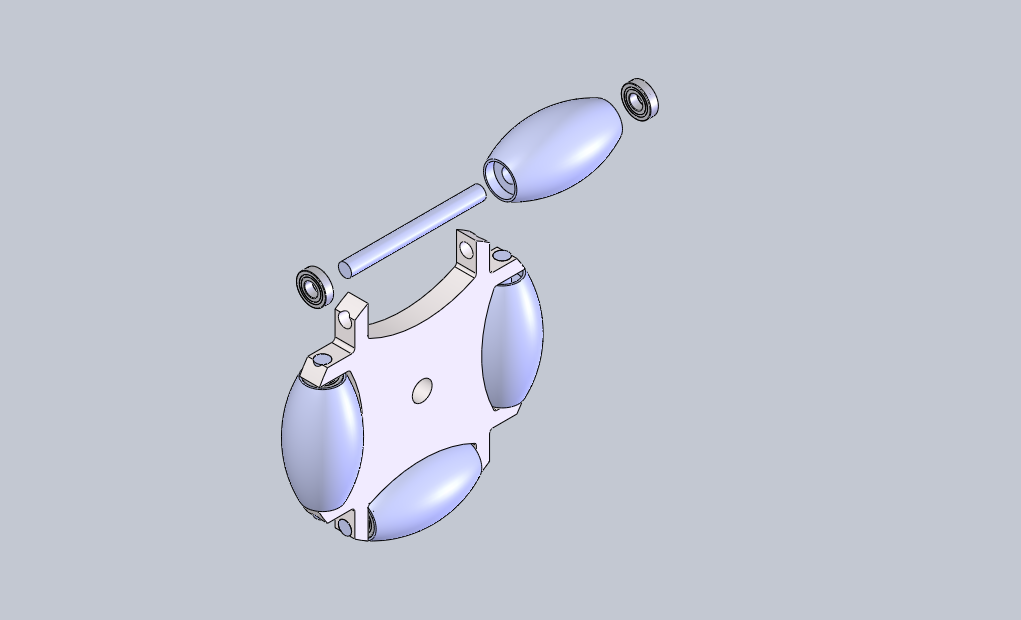

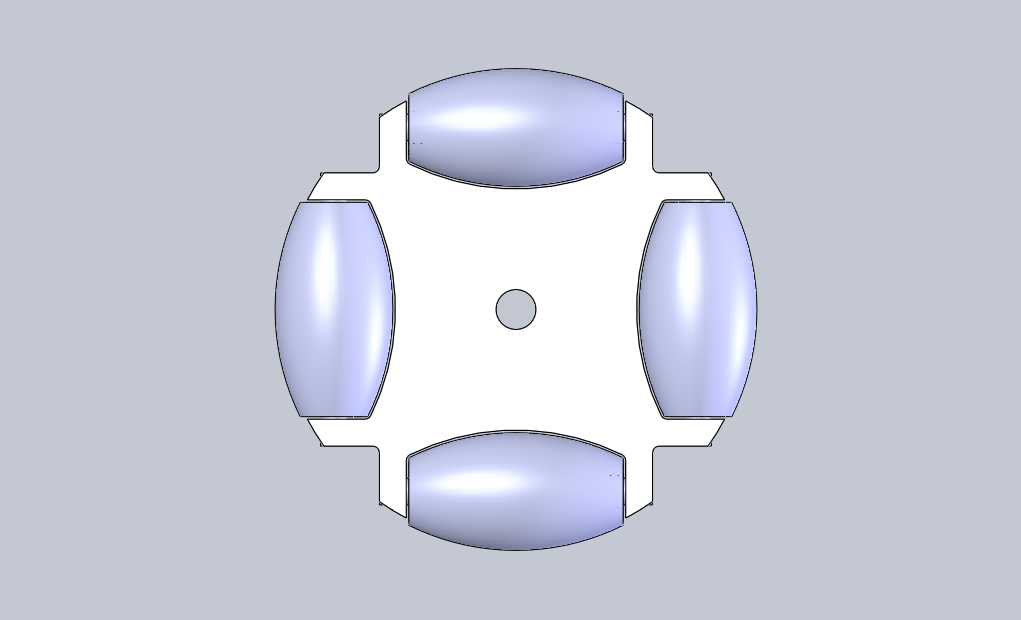

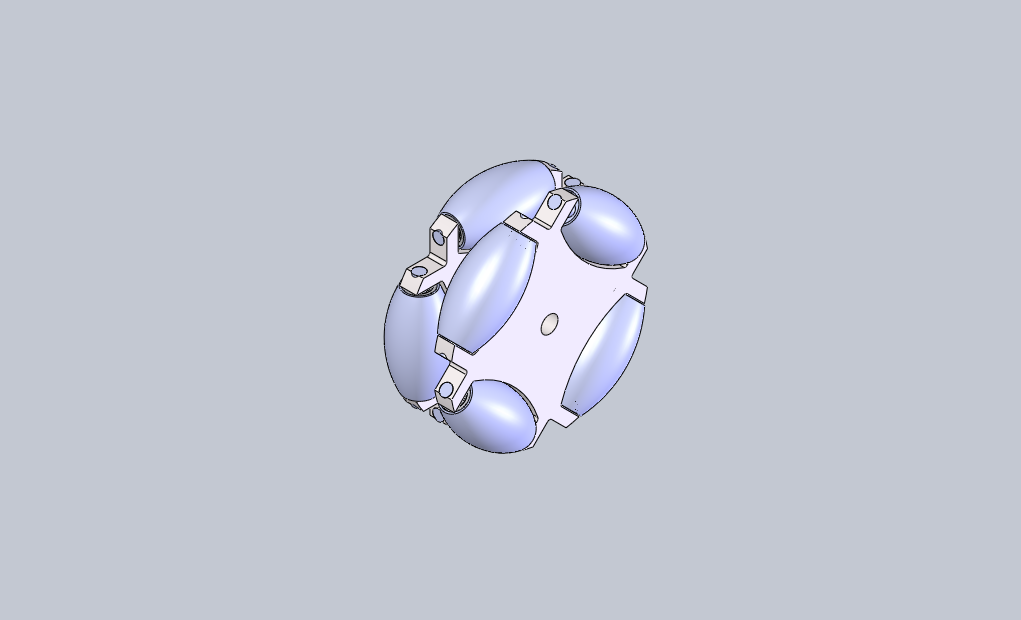

Automatically align to the front of the cubicle where the breaker is located

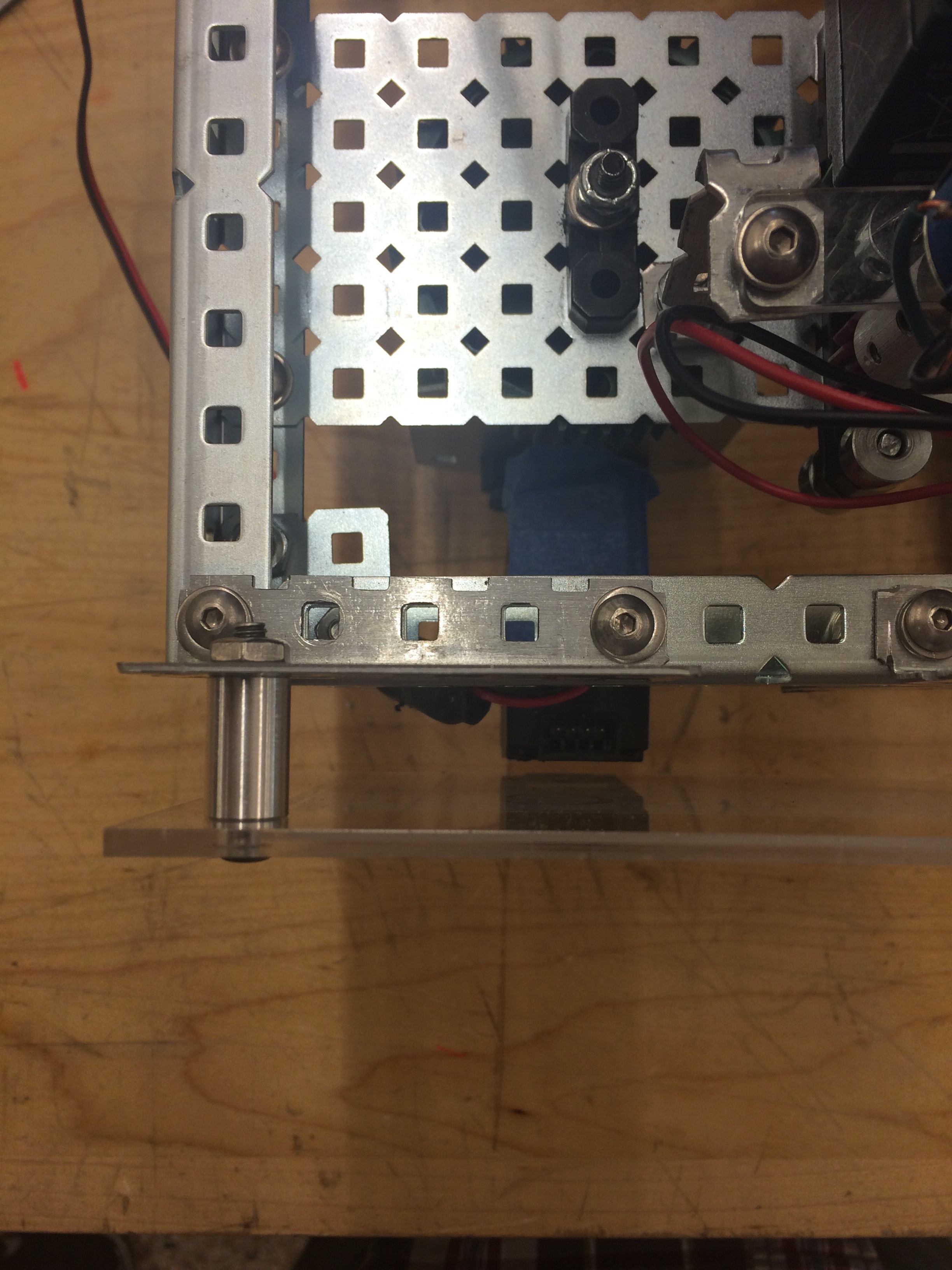

Automatically remove the breaker from the cubicle and reinsert it once aligned

We demonstrated these functions for them with our prototype, and we had a long conversation about the technical and logistical constraints that would need to be considered and accounted for in a full scale robot. As for sealing ConEd's commitment for next year, we are still working on the business aspect of the deal and that's really all I can say right now.

We did leave BreakerBot there so that it could be used to help secure funding for the project from the higher-ups who were unable to attend our presentation. It was hard to say goodbye to BreakerBot, but we are very happy to know that BreakerBot has a new home at ConEd.