Part of my job as an engineering education developer includes designing and manufacturing the parts needed for the activities. One of the activities I helped create was on the structural design principle of tensegrity. Tensegrity is a way to build structures that are lightweight and strong. They rely on flexible tensile elements such as strings, ropes, or cables; as well as on stiff compressional elements such as rods. Tensegrity structures are pre-stressed and self stabilizing, and none of the compressional members touch. They are suspended in a web of tensional elements, a phenomenon referred to as "floating compression" by artist Kenneth Snelson.

The activity itself is like a board game to teach students the entrepreneurial aspects of engineering. The activity centers around building a mini tensegrity tower. These towers use wooden dowels with notches cut in either end; rubber bands fit in these notches and hold the rods together in a simple tensegrity structure. The problem is that the balance and symmetry of the tower depends on the quality of the rods. All the rods must be made to a high standard, or else the tensegrity towers become very asymmetrical and unstable. This is because with different length rods, the rubber bands are stretched to different lengths and therefore exert different restoring forces. The imbalance of restorative forces within the structure causes the structure to shift in order to find a new equilibrium. This throws everything off.

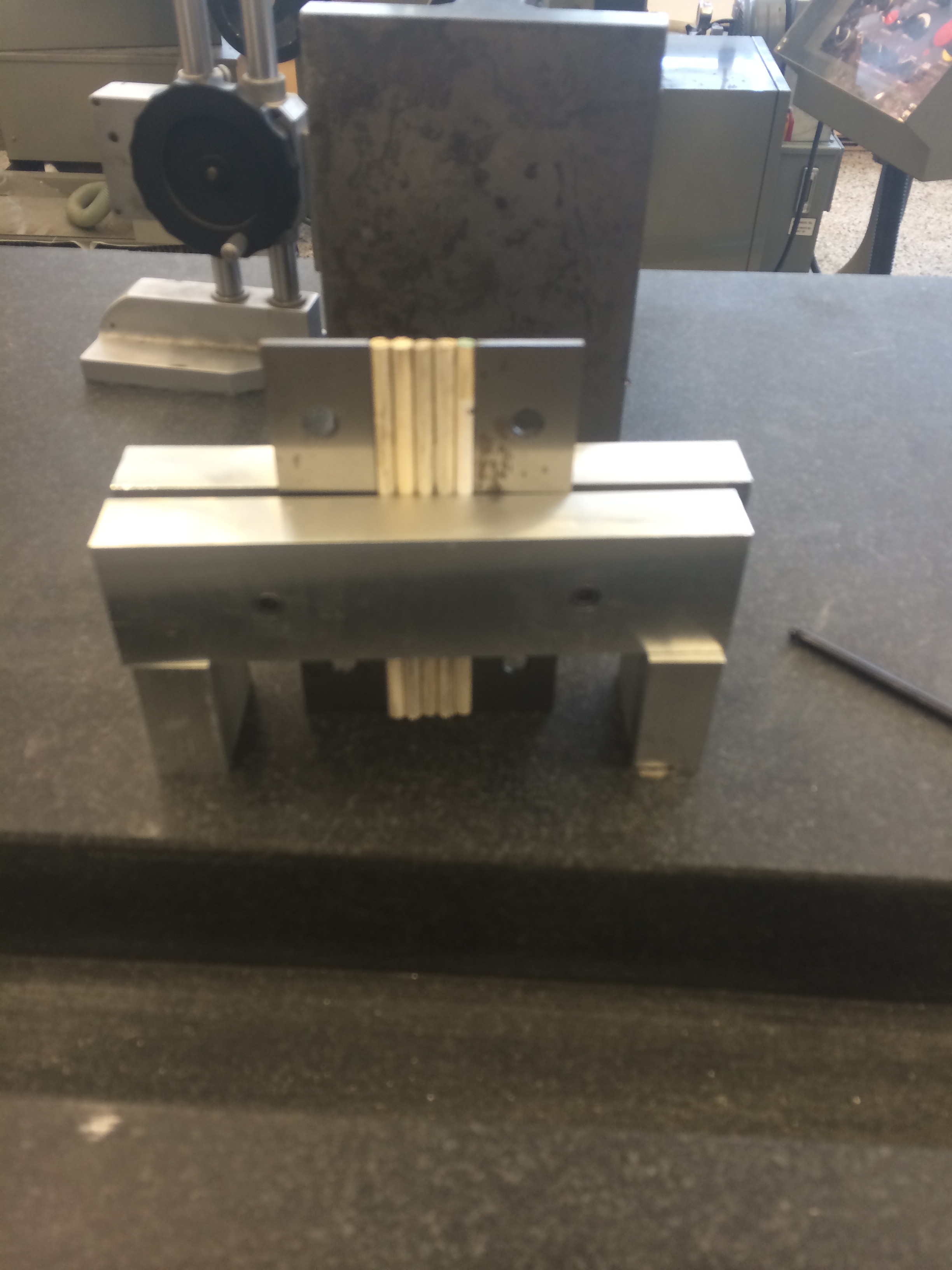

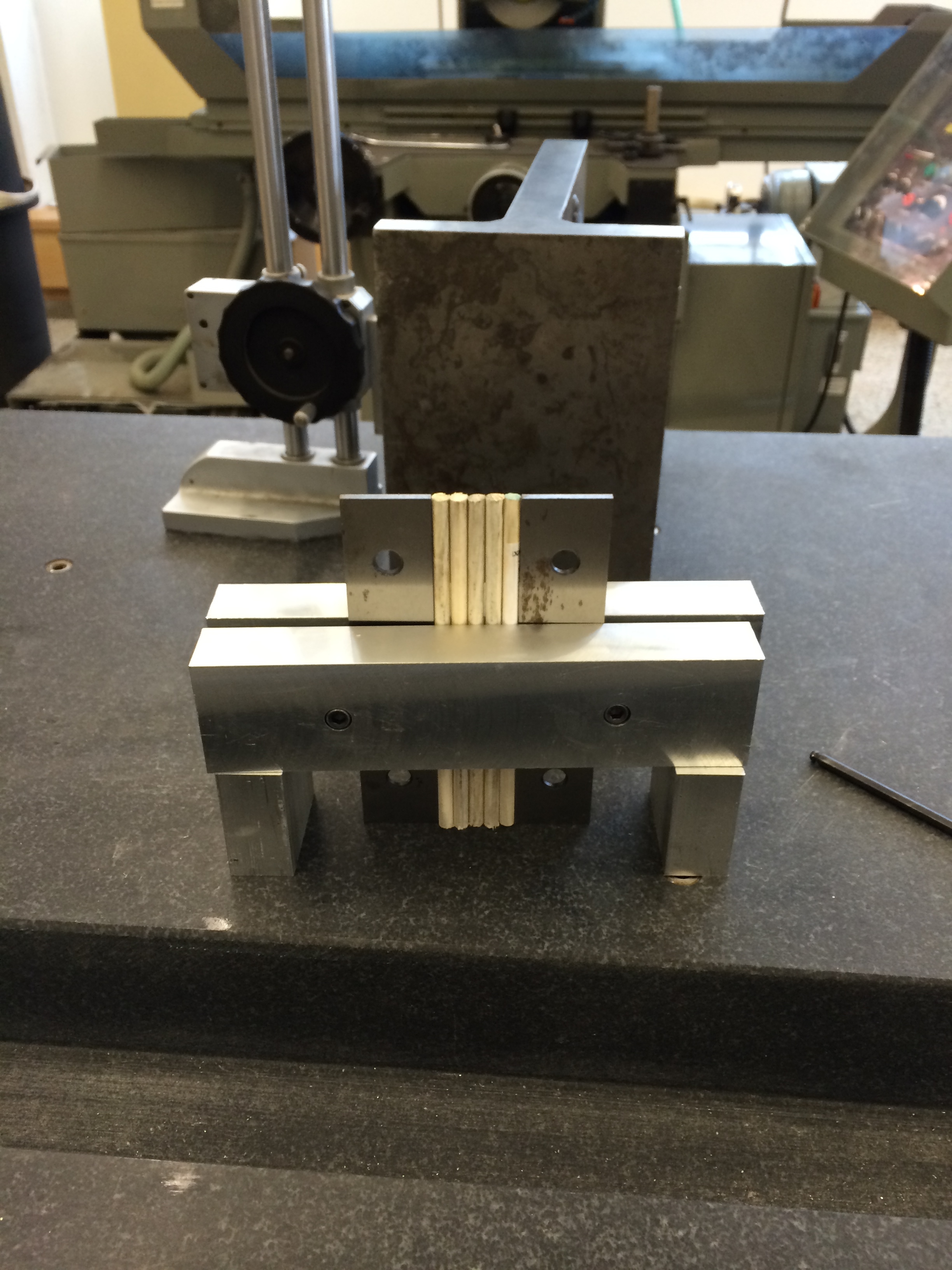

To make the towers as balanced as possible, a manufacturing method was needed to produce the rods very quickly and precisely. I decided to make a simple vise to hold the rods. The vise is clamped into the vise of a mill, which can be used to machine the notches on one end. Then, the inner vise can be flipped upside down to machine the other side of the rods.

There were a few caveats to this approach; the length of the rods compared to the size of the vise made it difficult to clamp into the mill's vise jaws. Additionally, the length of the dowels sticking out of the vise made it difficult to machine cleanly without using extra clamps to restrict the motion. All in all, however, it worked pretty well and I think these towers will perform much better.