This weekend was our graduation, and with everyone's family in town I took my girlfriend's sister to the machine shop to teach her some machining. She helped make part of the locket I'm making for my girlfriend. We had to cut shallow flat bottomed holes in the barrels for the pictures to go in. Because the barrels have a semicircular geometry, they could not be mounted on the table using a regular vise or any of that hardware. So we made a custom fixture to hold the barrel for the hole cutting operation.

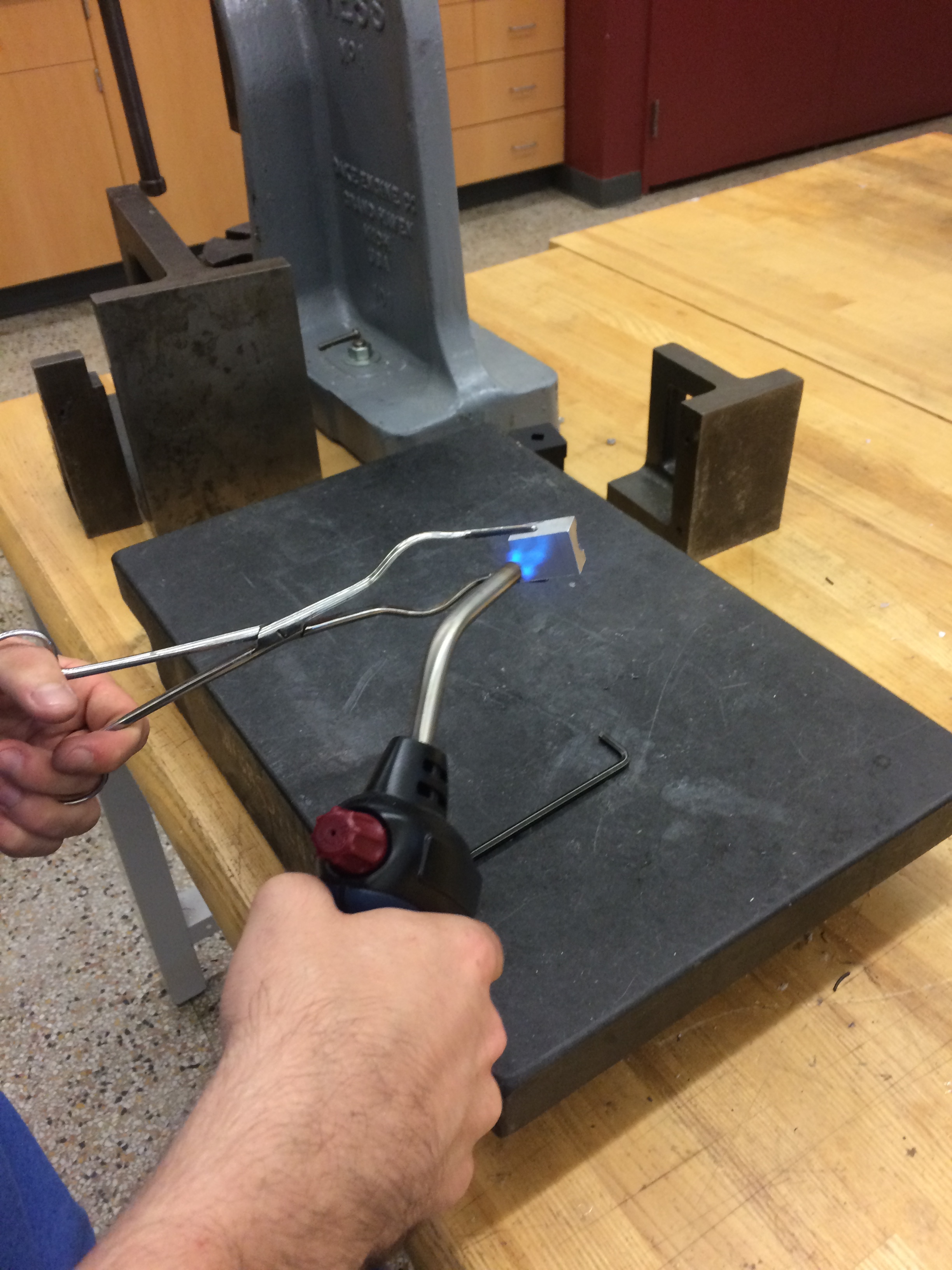

We used a 1/2" ballmill to cut a groove in a square piece of aluminum so that the 1/2" barrel would fit snug in the groove. We then superglued the barrel in the groove and clamped the whole thing in the vise to drill the hole .050" deep with a 3/8" flat end mill. We then heated it up with a propane torch to release the superglue bond and used some acetone to get rid of any residue. Superglue is a very easy way to fix parts that would otherwise require the manufacture of a complex fixture or jig. I don't know if I would trust it for precision machine work though.

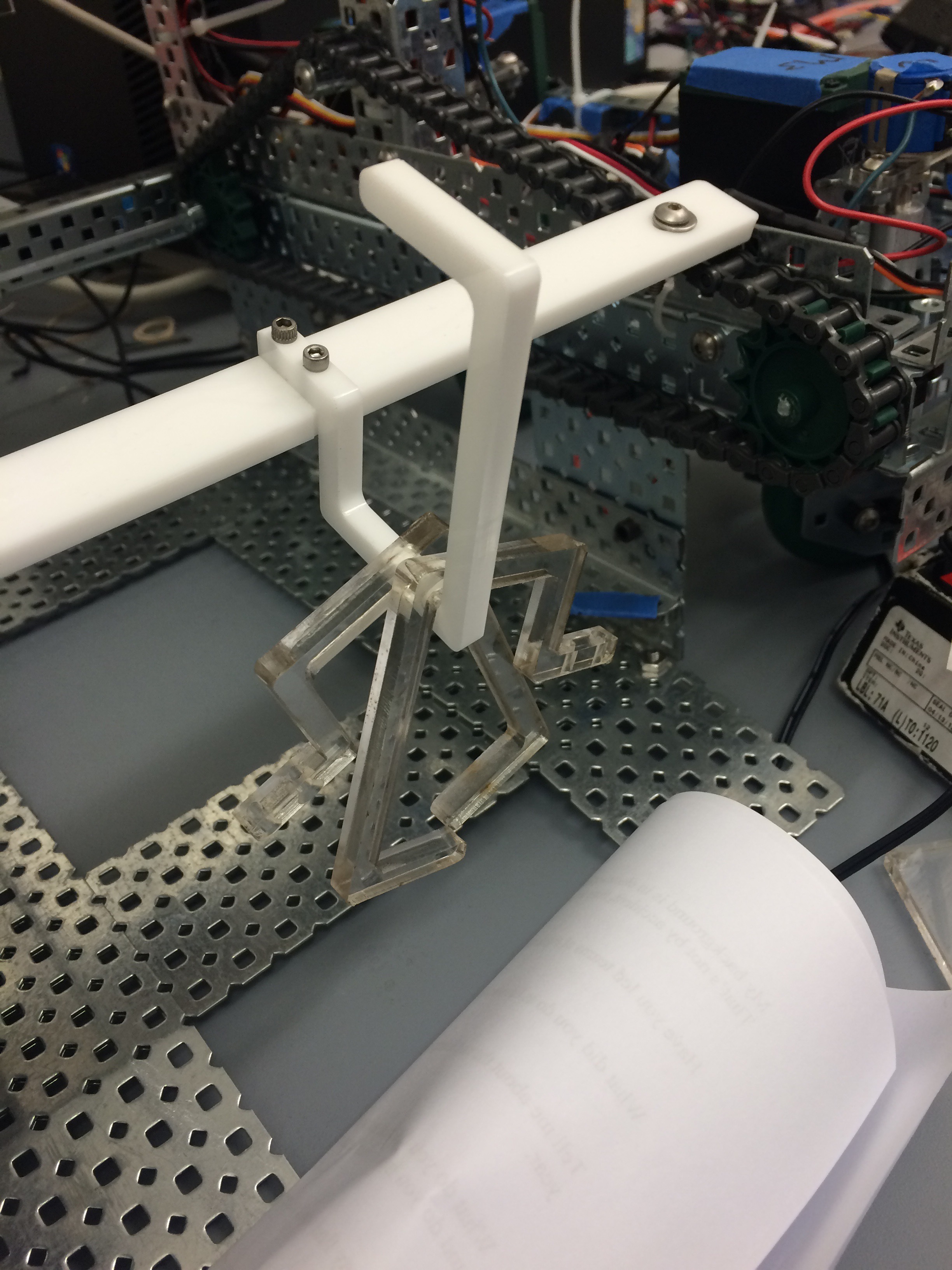

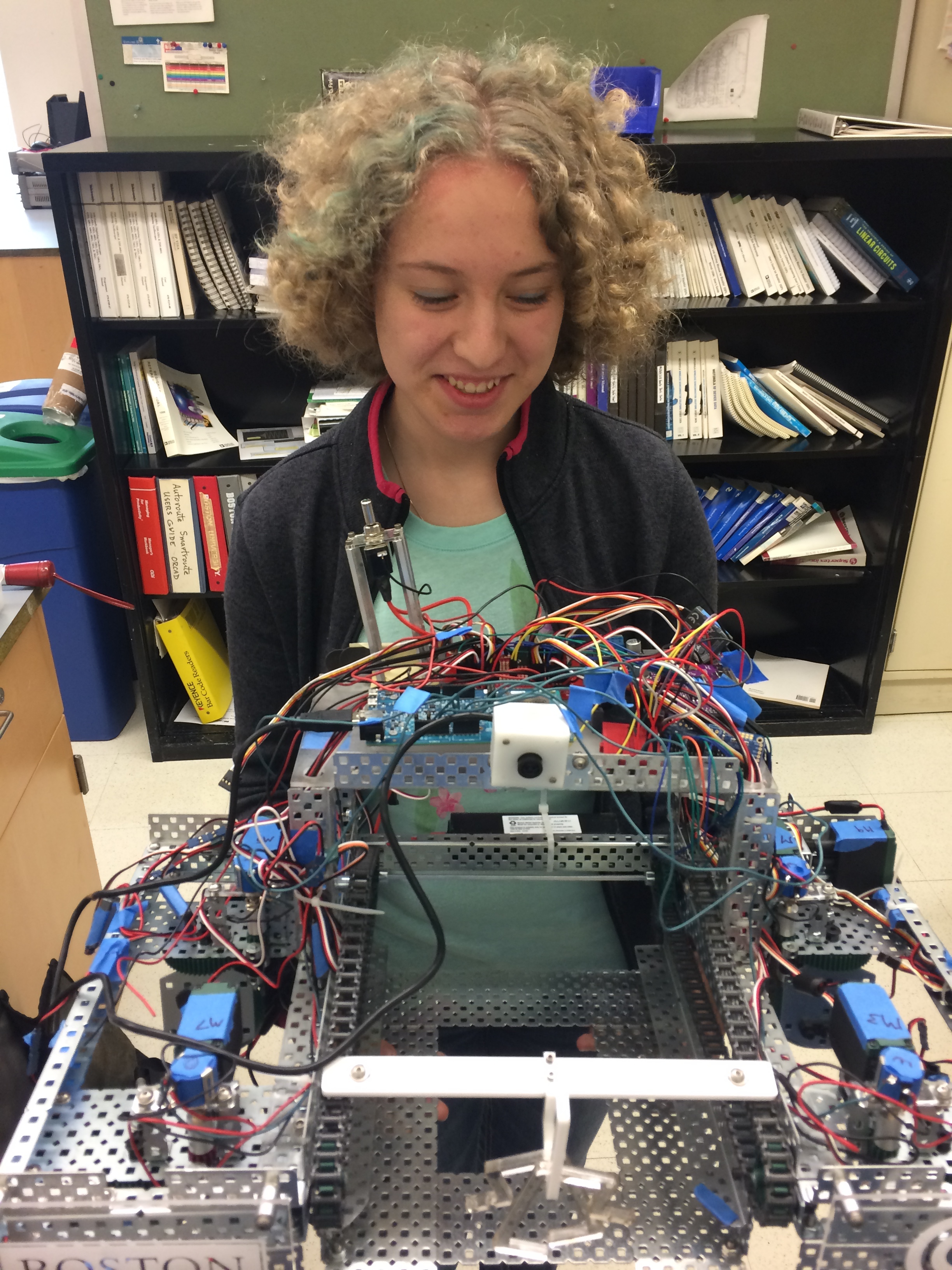

We also made some spare parts for our robot on the lasercutter, as we are taking it to ConEdison on Tuesday to present to them and we want to make sure it works!