Cable Tie Cutting Mechanism

This was a quick project in my Product Design class, meant to be an exercise in conceptual design. Our task was to design an original product that used waste material from a utility knife blade manufacturing process as a functional part.

Introduction

One of my projects for my product design class was for the Stanley Black and Decker Corporation (SBD); an American manufacturer of tools and hardware. Some of SBD's top selling products include utility knives and their blades. The blades are made from a roll of steel the same width as the blade. The roll is sharpened on one side to form the sharp edge of the blade, and then individual blades are stamped out. Unfortunately, because the roll is sharpened one side, the stamping of the blades cannot be tessellated like puzzle pieces to minimize waste. As a result, the stamping of each blade results in a triangular piece of waste material. The waste material from stamping operations is unique, because unlike the chips that result from machining processes, the waste material has consistent dimensions and structure. In other words, there was a possibility for SBD to use these triangular pieces to make something. Our job was to figure out what.

My primary design objective was to come up with an original product idea that uses the triangular piece. I did not want to simply make a version of an existing product that used this triangular blade instead of the one it normally uses; that would just result in an inferior knockoff. I thought the product should be something that seemed to belong in the SBD brand; i.e. a tool of some sort. Finally, I constrained the design to not require any manufacturing operations to be performed on the triangular blade; that would defeat the point of using the waste material in the first place!

Conceptual Design

After many hours of brainstorming and deliberating, I realized that there didn't seem to be a tool designed specifically for cutting zipties, or at least not one that was well known. I recall many instances of removing zipties in which I was searching for an adequate tool to do so. Scissors are probably what most people at home or in the office have lying around, but depending on how tight the ziptie is you may not be able to get the blade underneath to cut the tie, and you also run the risk of damaging whatever the ziptie is holding by trying to force your scissor underneath. Using an hobby knife or a utility knife is a little easier, but also more dangerous if you decide to pull the blade towards you to make the cut. I decided to design a tool that would use the triangular blade to cut zipties. A quick google search showed that products designed to cut zipties already exist, however they seemed to be marketed to industrial workers who would need to fasten/cut hundreds of zipties per day. I designed my product to be marketed more to someone who needed cut fair amount of zipties and wanted to do so efficiently and safely, but didn't feel the need to buy a more expensive industrial tool.

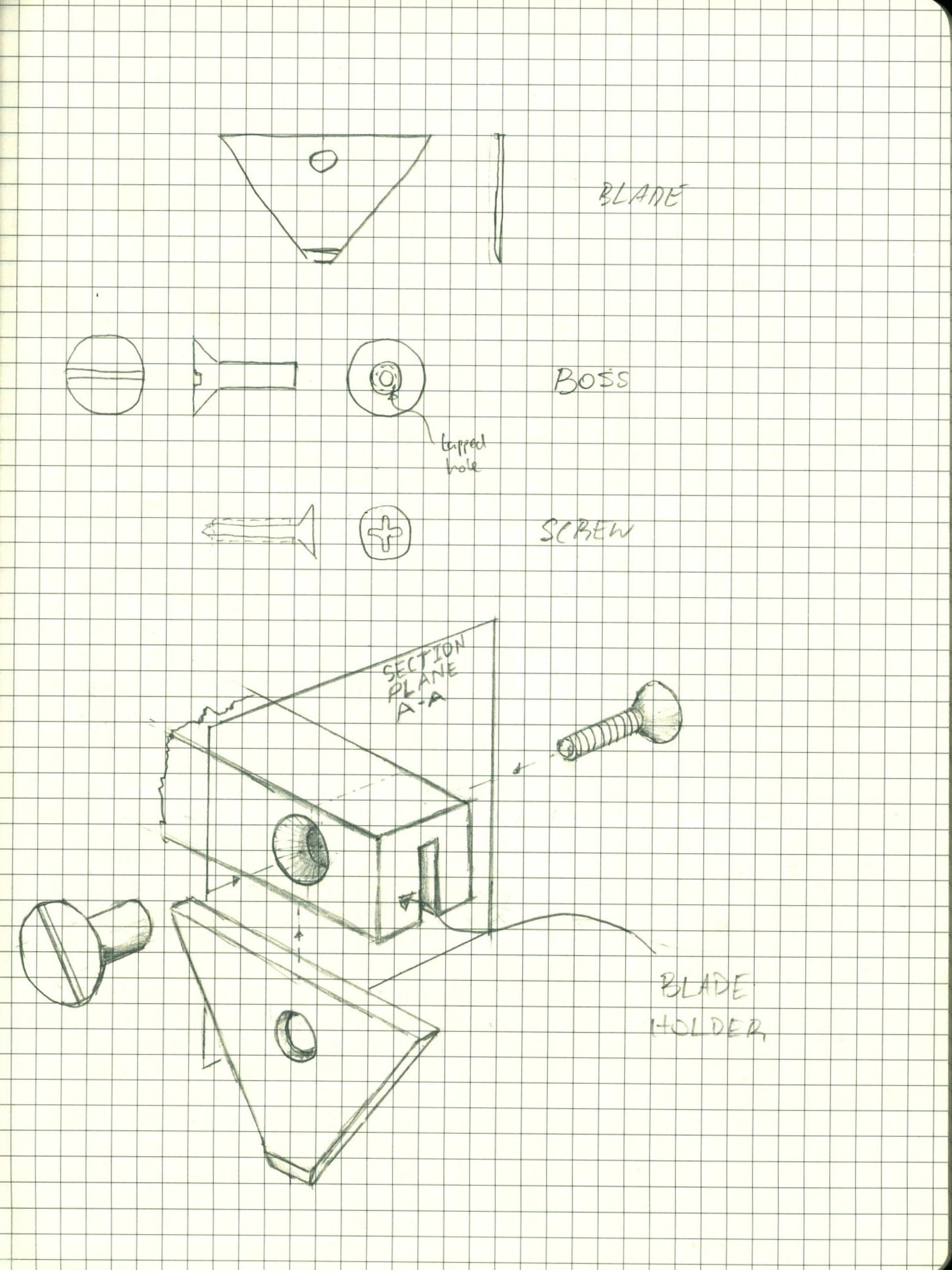

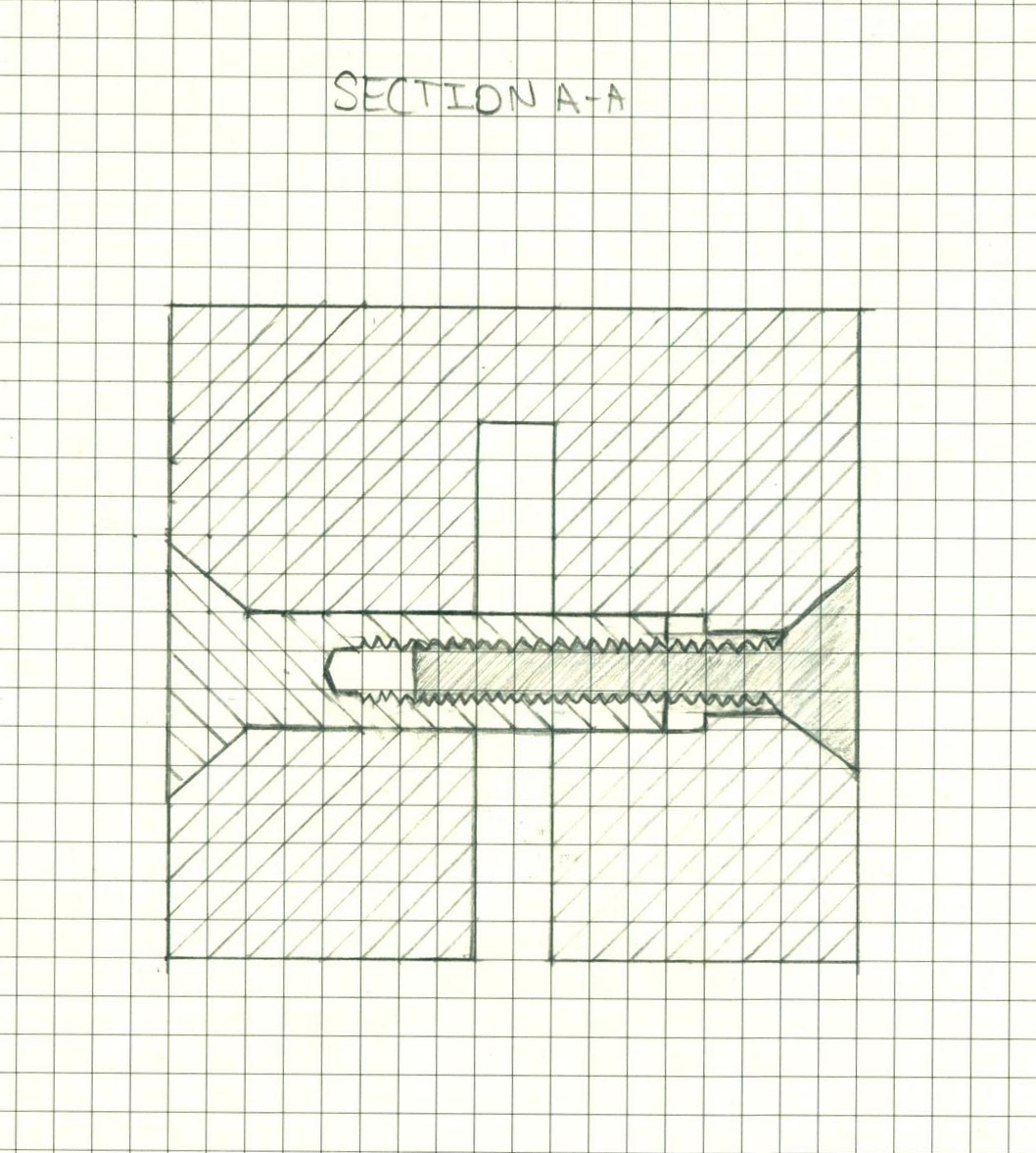

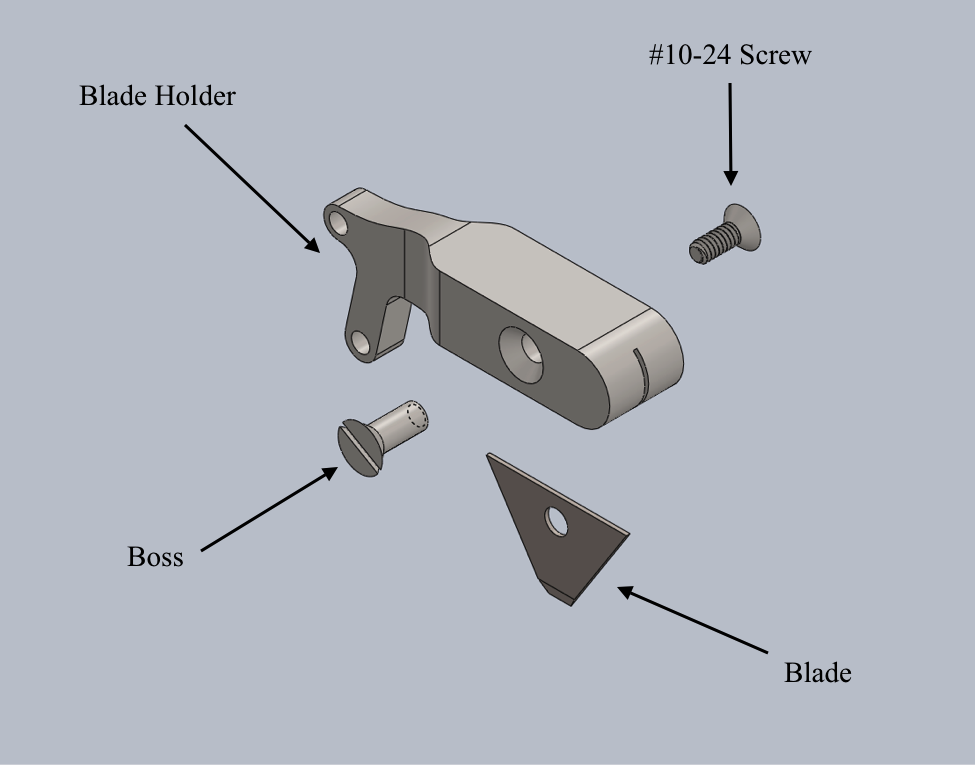

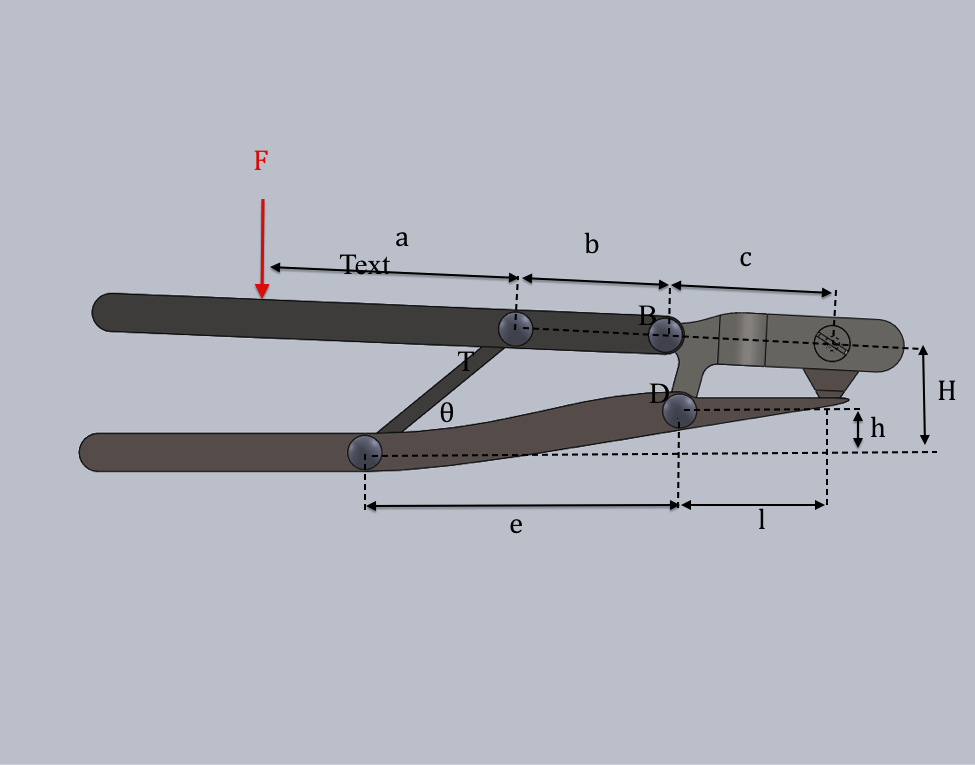

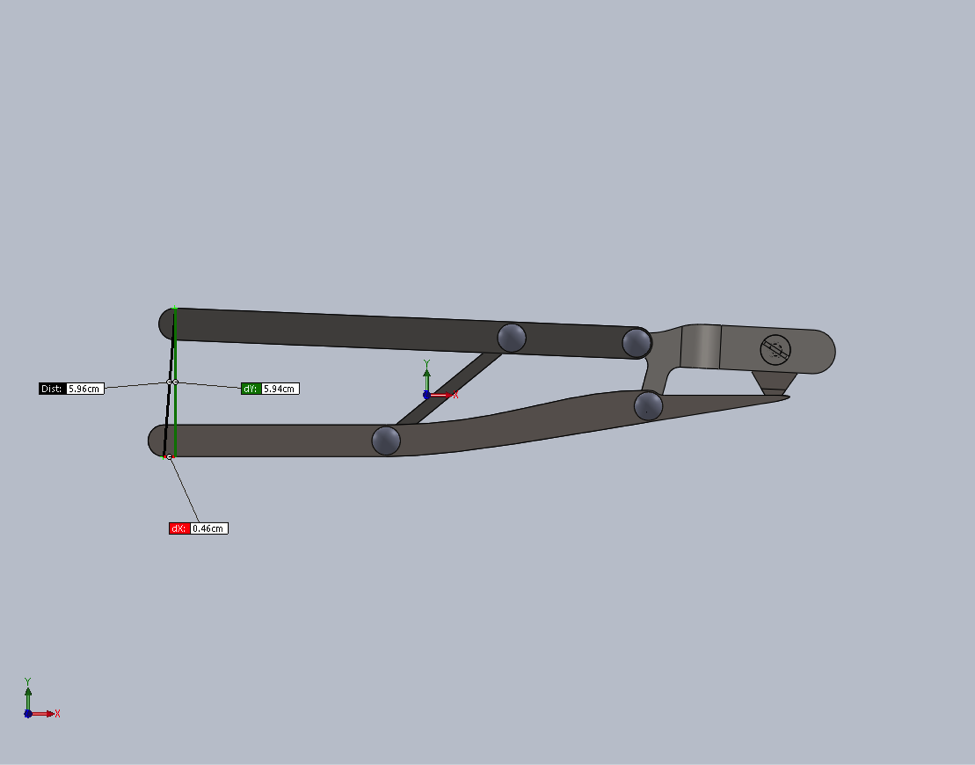

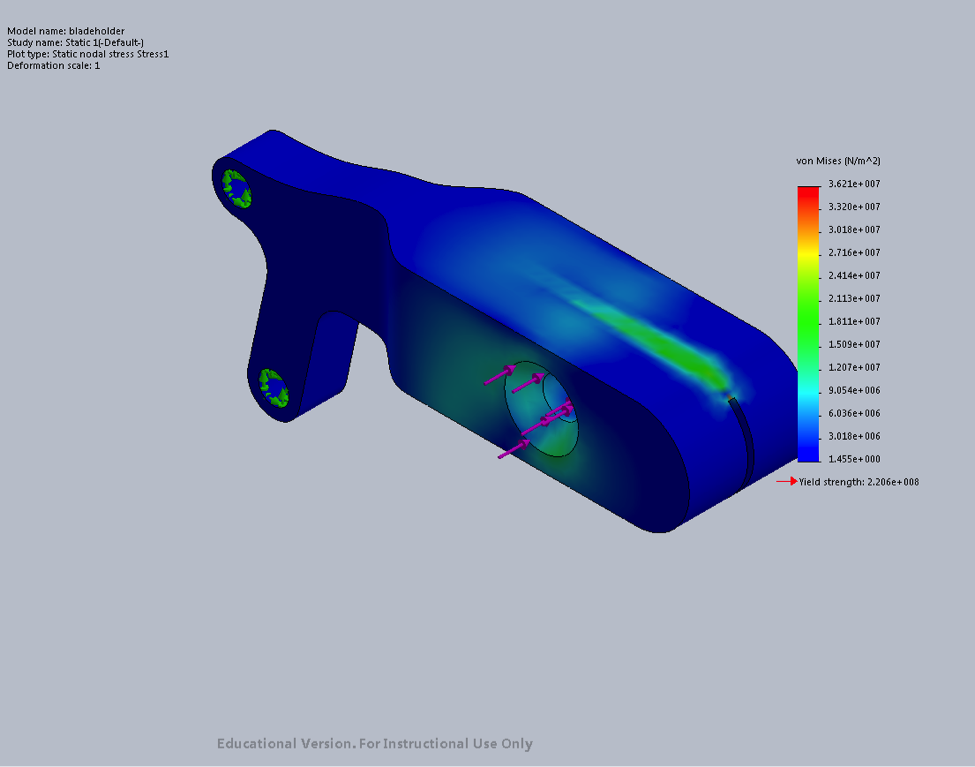

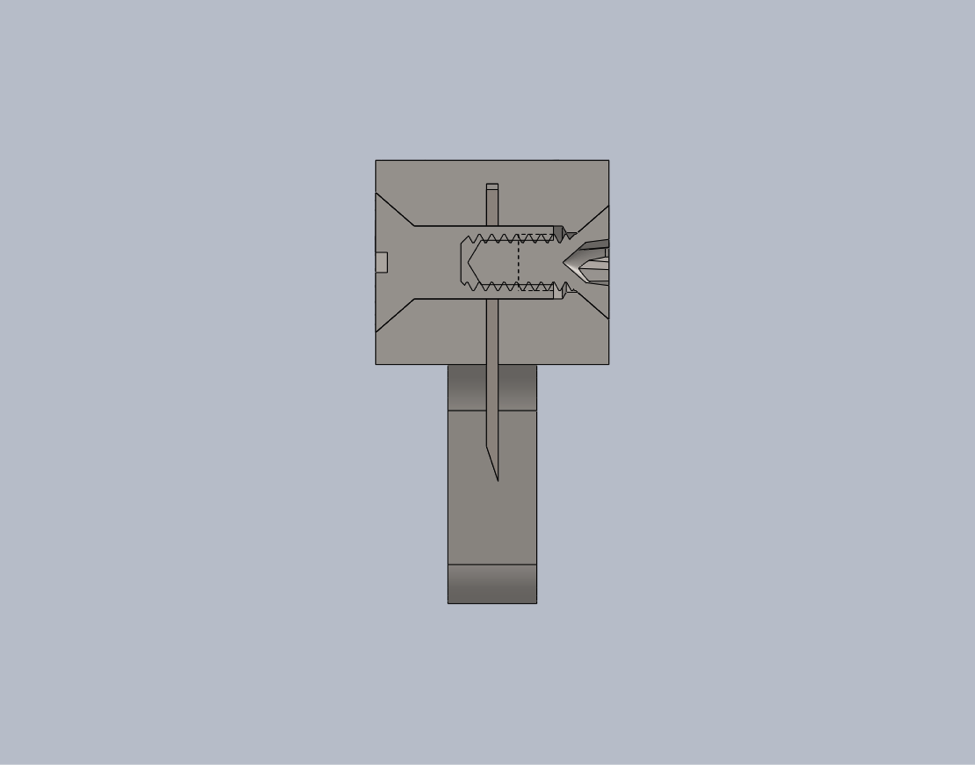

My initial idea was for the device to work via a four bar mechanism similar to locking pliers or vise-grips. The blade would clamp down on the ziptie against a protective wedge that was part of the lower handle, which also acted to protect the materials underneath. The blade would be secured via a clamping force provided by a threaded insert ('boss') that goes through the hole in the blade. The boss and its mating #10-24 screw would be countersunk to fit into the blade holder flush, although this is more for aesthetic than function. By tightening the screw and the boss against each other, the sides of the blade holder would clamp down on the blade, thereby securing it. A torsional spring would also be used in the mechanism to make sure its default was in the open position.